Search To Find The Right Solution

Shop Quickship48™

Latest Blog Post

Force Sensors Automate Safety Systems in Industrial Facilities

Interface force sensor technologies help modernize industrial facilities by providing valuable data to monitor and improve worker safety. Our load cells, torque transducers, and multi-axis sensors are used for overload protection, quality control systems, lockout and alarm systems, equipment monitoring, robot and...

Read The Latest PostMore Blog PostsLatest App Note

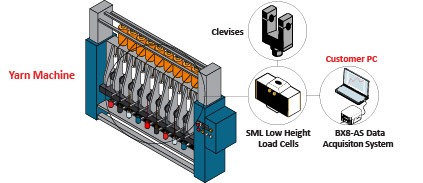

Yarn Tension Monitoring

Interface’s SML Low Height Load Cells can monitor the force of the individual yarn strings on the track wheel. SML's are attached to a clevis, which is then attached to a track wheel that holds the yarn in the machine. When yarn...

Read MoreMore App NotesMaximizing Efficiency with Load Cells in Mining Equipment

By accurately measuring the weight of bulk materials, Interface’s load cells help mining companies optimize their operations, enhance safety, and maintain compliance with industry regulations. Whether it’s monitoring payloads, tracking material flow, or controlling conveyor systems, our load cells are indispensable tools that contribute to improved productivity and profitability in the mining sector.

Load Pin Brochure

Weighing Solutions Brochure

Data AQ Pack Brochure

Enclosures Brochure

BlueDAQ Software Brochure

OEM Brochure

Low Profile Load Cell Brochure

Multi-Axis Sensors

Calibration Load Frame

BX8 & 6-Axis

BSC4 & 3-Axis

Torque Transducers

Load Button Load Cells

AxialTQ

Accessories

Instrumentation

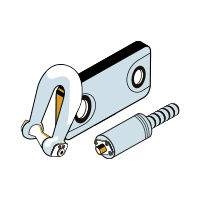

Load Pins, Tension Links, & Shackles

Interface Mini™ Load Cells

Calibration Systems

WTS & BTS Telemetry Systems

Digital Instrumentation

Blue Economy Solutions

Manufacturing Solutions

Natural Resources Brochure

Construction Solutions

Robotic Solutions

Lifting Solutions

Space Economy Solutions

CPG Solutions

Entertainment Solutions

IoT Solutions

Energy Solutions

Education Solutions

Infrastructure Solutions

Test and Measurement Solutions

Automotive and Vehicle Solutions

OEM Solutions

Maritime Solutions

Agriculture Solutions

Medical and Healthcare Solutions

Aerospace Solutions

Industrial Automation Solutions

Interface Products

Interface products are the world’s best sensors for force and torque measurement.