To design and build an aircraft, there are incredibly strict standards to meet to ensure the vehicle is safe and can hold up to regular use and the elements over time. Structural tests play a critical role in ensuring the aircraft is approved for flight. Aerospace manufacturers utilize a wide variety of tests to develop various components involved in the aircraft, one of which is static testing. The static rig test is the most basic and important one of all structural tests. It is the safety verification of a test specimen’s structural design, and it is an important basis of test specimen’s modification.

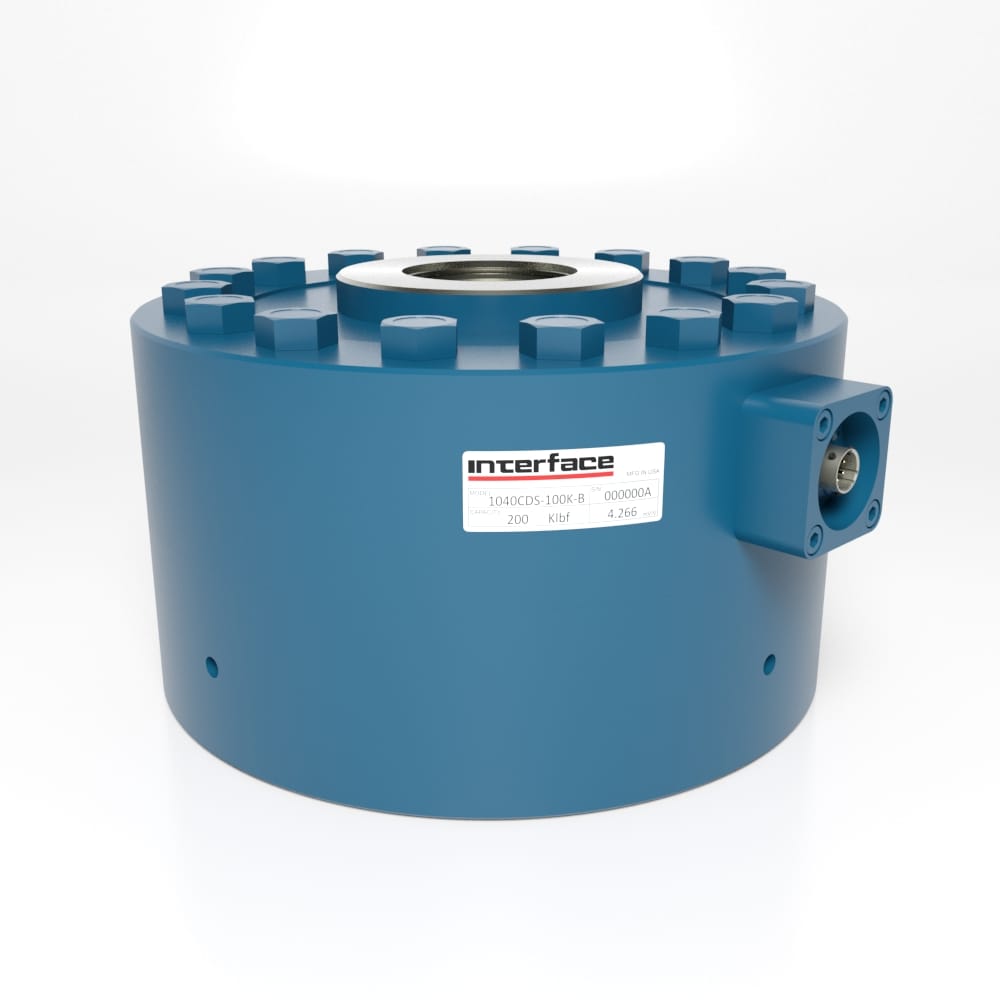

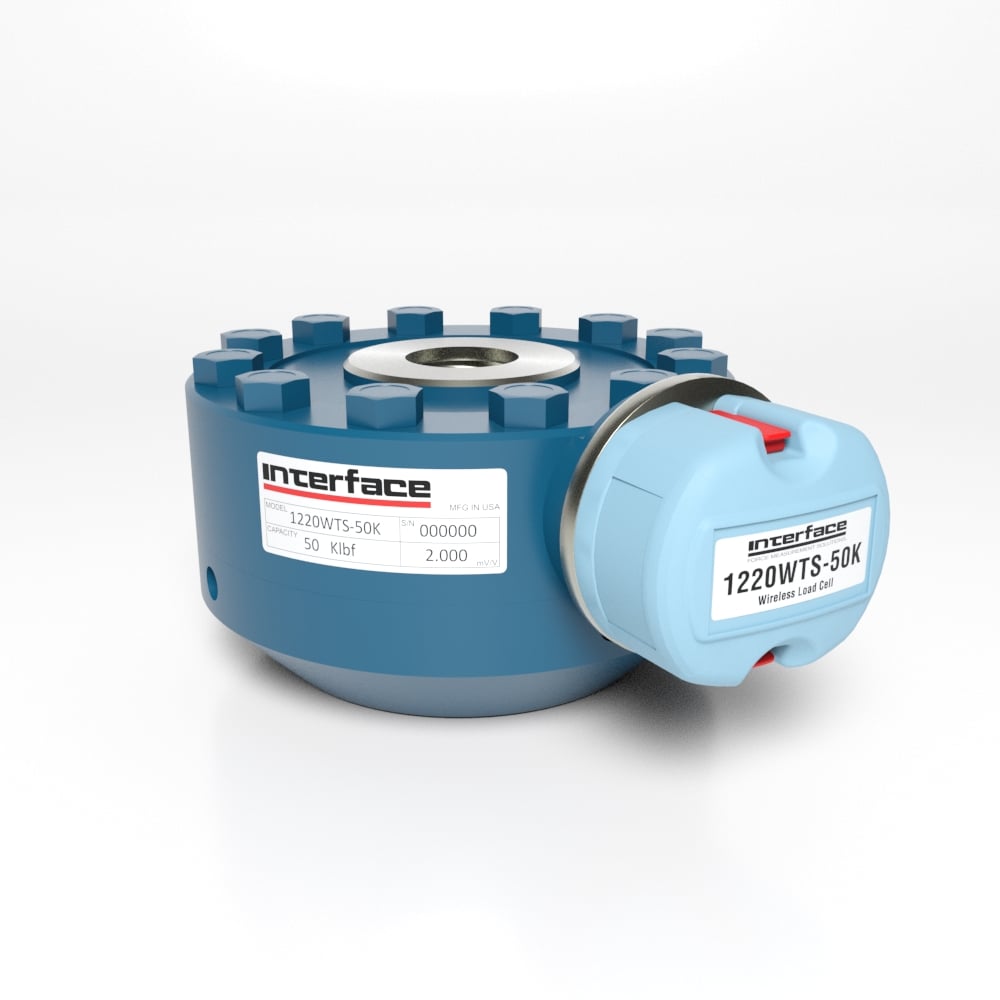

To perform a static test, a variety of equipment is necessary including high-reliability and very high accuracy load cells. Load cells can be used to test frame structure integrity, endurance, and life cycles, with the goal generally being to validate aircraft design and ensure specified criteria are met. The strict accuracy is necessary because in aerospace, every micrometer and gram make a difference in both the performance and safety of an aircraft design.