An Interface customer who manufactures robotic arms needed a solution to measure both the force and torque of a robotic arm as it picked up and placed objects onto a conveyor belt. Due to the complicated movements of the robotic arm on multiple axes, the customer needed a more advanced solution that could measure the force in all directions. Interface supplied a Model 6A40A 6-Axis Load Cell and a Model BX8-HD44 Data Acquisition and Amplifier device. The multi-axis load cell and data acquisition devices were able to log, display, and graph these measurements while sending scaled analog output signals for these axes to the robot’s control system. This testing process helped the customer refine each motion of the robotic arm and ensure accurate force of the grapple arm.

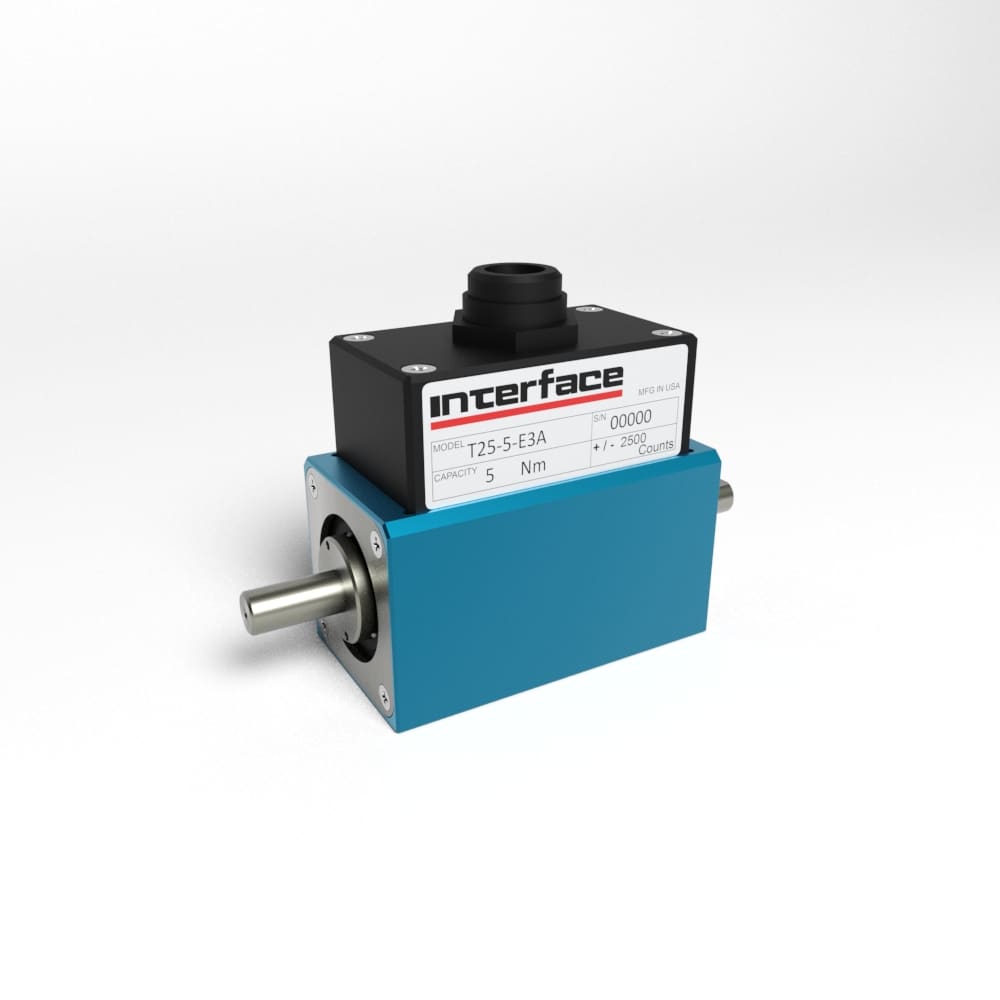

Another robotic application of Interface force measurement product is in the drone delivery services field. Many shipping plants are introducing the use of drones to deliver packages more quickly and efficiently to consumers. One of the critical components to ensuring drones can successfully deliver packages is by optimizing the amount of torque it takes the propeller motor to lift and fly with a package of various weights. To do this, Interface provided a 1200 Series Standard Precision Low Profile Load Cell to measure the weight of the payload and six T2 Series Ultra Precision Shaft Style Rotary Torque Transducers to measure the torque of the propeller. In this application, the Interface torque transducers remain on the drone throughout the flight process to monitor and record torque data in real-time.

Interface was asked by a customer to supply a solution for a candy stamping press. Interface developed a test apparatus with a Model WMC Mini Load Cell and attached it to hydraulic actuators to measure the compression force. Using this apparatus, the customer was able to determine the specific force needed to properly stamp the candy without breaking it. With a stamping press in either the medical or consumer packaging industry, load cells can also remain on the machine to monitor the force in real-time and let the line engineer know if service is needed on the