Force Sensing Keeps Factories Running Feature in Fierce Electronics

In the recent article, ‘May the force be with you: Force sensing keeps factories running, product quality high’ Dan O’Shea at Fierce Electronics writes about the growing demand for sensors in industrial automation applications.

Following his interview with Interface’s Keith Skidmore, Dan writes:

‘While some sensors are more focused on monitoring equipment or measuring environmental conditions around a manufacturing process, force sensors measure mechanical forces occurring in the equipment and processes, and the products being manufactured. They measure things like load, tension, resistance, weight or total pressure applied. By employing this kind of sensing technology, manufacturers can monitor the health of their equipment and improve quality assurance for their products.’

“Testing things by applying a force to them is super common. Many products in lots of industries get tested this way, from aerospace to automotive, through to consumer goods. Chairs, furniture, mattresses, ladders–basically, anything that’s being manufactured, there can be a desire to figure out how strong the various parts of those products are.” Keith Skidmore, engineer and regional sales director at Interface

Read the entire Fierce Electronics article here.

Interface provides industrial automation and IoT solutions to manufacturers, equipment makers and factories around the world. Sensors play a pivotal role in production and optimization through tools and process improvements.

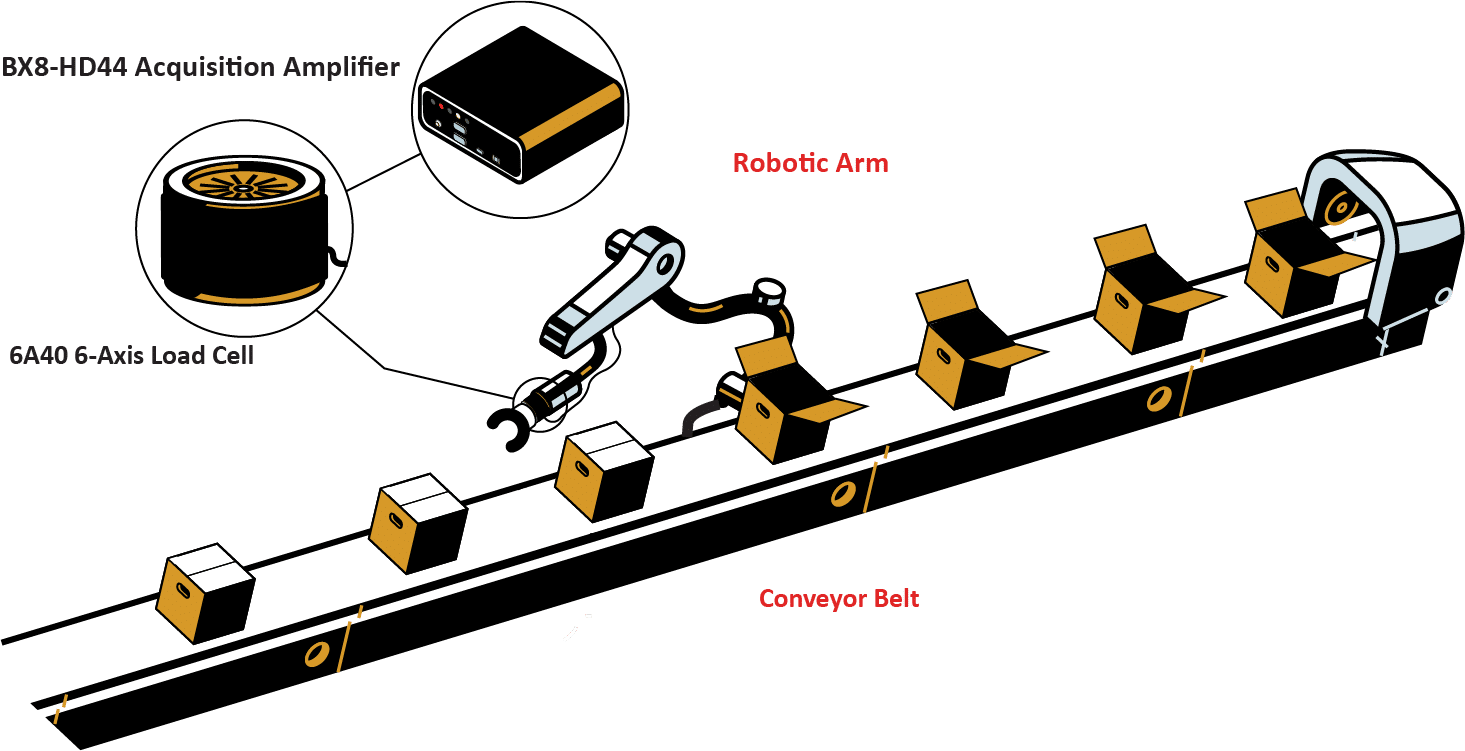

Industrial Robotic Arm

Robotic arms are frequently used in production facilities throughout the manufacturing process. Suppliers of these devices heavily rely on accurate and quality sensors to provide feedback. In this application, the designer needed to test the force of the arm apparatus to ensure it could safely secure packages on a moving conveyor belt without damaging any materials or products. This automated function helps to improve quality of packaging and increase productivity on the line.

Interface provided the model 6A40A 6-Axis Load Cell with model BX8-HD44 Data Acquisition Amplifier instrumentation. The 6-Axis load cell provides measurement of all forces and torques (Fx, Fʏ, Fz, Mx, Mʏ, Mz) and the BXB-HD44 Data Acquisition Amplifier logs, displays, and graphs these measurements while sending scaled analog output signals for these axes to the robot’s control system. Customer installed 6A40 6-Axis Load Cell between robot flange and robot grabber. The extensive data outputs from the multi-axis sensor provided the exact detailed measurements needed for the industrial robotic application.