Present and Future Interface Calibration Product Family

Calibration of force measurement tools is integral to accuracy and success in product design and development. As a follow-up to our feature on our expert calibration services, here is a quick introduction to some of our current and future calibration products.

Calibration of force measurement tools is integral to accuracy and success in product design and development. As a follow-up to our feature on our expert calibration services, here is a quick introduction to some of our current and future calibration products.

The calibration product family includes five calibration systems that are designed for various needs and force measurement parameters. These systems include:

- 55K lbf and 110K lbf Automated Calibration System and 2K lbf Automated Calibration System

- 2K lbf Load Cell Verification System

- Next Gen High-Resolution Signal Conditioning Board (HRSBSC)

- 4 Channel 9840-400-1-T Intelligent Indicator

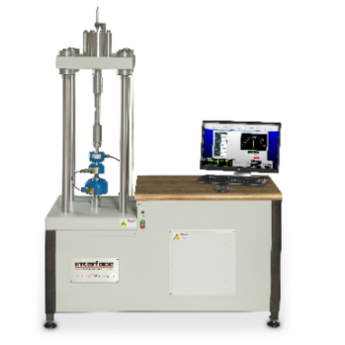

55K lbf and 110K lbf Automated Calibration System and 2K lbf Automated Calibration System

The 55K lbf and 110K lbf Automated Calibration Systems are Interface’s most popular systems because two capacities represent the two most popular capacities requested by customers.

“These systems allow customers to speed up their calibration process because rather than outsourcing calibration, it can all be done in-house.” Ted Larson, VP of Product Development

The systems are unique in the industry because unlike competitor products, they feature a fully automated system that can measure both tension and compression in a single setup. These systems are designed to satisfy the calibration needs of the test and instrumentation, automotive, aerospace and metrology industries.

The systems are unique in the industry because unlike competitor products, they feature a fully automated system that can measure both tension and compression in a single setup. These systems are designed to satisfy the calibration needs of the test and instrumentation, automotive, aerospace and metrology industries.

The 2K lbf Automated Calibration System, which is on track for release in Q2 of 2019, will offer the same level of accuracy, consistency and excellence as the 55K lbf and110K lbf Systems, but is designed for low-end capacity load cells. This system will serve as a bench top unit and integrate with the same software as the 55K lbf and 110K lbf Systems. It is being designed to serve the medical and automation industries.

The 2K lbf, 55K lbf and 110K lbf Systems will be able to be integrated to work as a dual range system for customers who need to calibrate a wide range of load cells. Both systems utilize our industry-leading gold and platinum standard load cells, which provide the highest accuracy in the industry.

2K lbf Load Cell Verification System

The 2K lbf Load Cell Verification System is another calibration product that is on track for a Q2 2019 release. This system is being designed as a direct response to OEMs who deal with large volumes of load cells and need a quick, low-cost way of verifying load cells used in equipment. Currently, customers who suspect a calibration issue are often forced to remove load cells from equipment and be sent in to be repaired, recalibrated or to receive a new load cell. This process and the resulting downtime costs money due to lack of production, and there is often no issue present with the load cells.

The 2k lbf Load Cell Verification System can identify a calibration or performance issue, allowing the customer to accurately determine if the load cells need to be replaced or need a tune-up, significantly reducing unnecessary downtime.

Next-Gen High-Resolution Signal Conditioning Board (HRSBSC)

The High-Resolution Signal Conditioning Board, which Interface pioneered more than three decades ago, will be receiving an innovation update to improve performance and capabilities. The HRSBSC is designed for use with Interface Gold Standard Calibration Systems and can be provided in a single or dual channel solution. This product’s primary industries include test and instrumentation and metrology. The development of Interface’s Next-Gen HRSBSC is slated for Q4 of 2019.

4 Channel 9840-400-1-T Intelligent Indicator

Interface recently introduced a new version of the 4 Channel Model T which features a more modern display with additional channels available. It’s now easier to use and has the same high stability and industry-leading performance as the older version of the 9840. Although the quality is the same, the updated version can be integrated with Interface’s Gold Standard® system and frames, as well as with Windows 10.

The 4 Channel Model T 9840-400-1-T Intelligent Indicator allows single loads with three measurements to directly compare outputs to Interface’s Gold Standard load cell, and all measurements can be captured through Interface’s Gold Standard software. This allows users to compare multiple load cells and gather data on whether the load cells are accurate or uncalibrated. The 4 Channel Model T solution also has the option for high-level input channels.

Stay tuned for updates on current and upcoming additions to our family of innovative calibration products.

Contributor: Ted Larson, VP of Product Development and Marketing, Interface