Showcasing Load Pin Versatility and Adaptation

One of Interface’s elite force measurement product families is our load pins. They are more than just replacements for standard pins, clevises, and pivot pins. They are powerful measurement devices many industries use to obtain real-time data for performance monitoring, quality control, operational support, and safety.

One of Interface’s elite force measurement product families is our load pins. They are more than just replacements for standard pins, clevises, and pivot pins. They are powerful measurement devices many industries use to obtain real-time data for performance monitoring, quality control, operational support, and safety.

Interface Load Pins are machined from high-tensile stainless steel and are suitable for all settings, including exposed environments such as seawater. They are used in heavy machinery in industrial factories and submersible energy generators in the ocean. Here is a quick reminder about the advantages and benefits of Interface Load Pin solutions.

- Versatility: Suitable for diverse applications in construction, infrastructure, aerospace, maritime, energy, and manufacturing.

- Durability: Rugged stainless steel construction, high IP rating, and waterproof design withstand harsh environments.

- Safety: Real-time load monitoring, alert capabilities, and intrinsic safety options enhance operational security.

- Cost-effective: Easy to retrofit without complex integration or redesign.

- Smart capabilities: Integration with various control systems, digital output, and remote monitoring options.

- Configured to unique requirements: Our robust configuration tool enables you to outline your specific measurement project requirements. Are you looking to embed the load pin into existing equipment, start a new testing project, or need an innovative force measurement OEM solution? Our experts have decades of precision load cell engineering and manufacturing experience.

EXPLORING LOAD PIN APPLICATIONS ACROSS INDUSTRIES

Load pins are ideal for measuring tensile and compressive forces in lifting and rigging, structural assemblies, and various applications. From energy, agriculture, and infrastructure to manufacturing, submersible vehicles, and environmentally exposed lifting equipment, load pin load cells provide reliable, accurate, and low-risk force measurements. Here are some inspiring use cases of how Interface Load Pins are used in different industries.

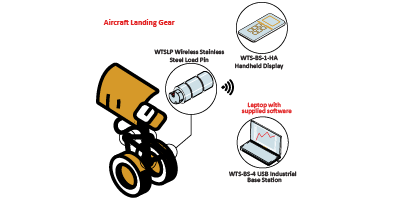

Wireless Load Pins Test Spacecraft Landing Gear

An aerospace company wants to test its new spacecraft assembly and design by testing its landing gear joints. They want to ensure no flaws in the gear shock absorber design and that it can handle the applied forces when the craft lands from a flight. Interface’s WTSLP Wireless Stainless Steel Load Pins can be installed and replace the normal pin joints. The spacecraft undergoes multiple drop tests at different heights, where the forces applied on the load pins are measured. The force results are transmitted wirelessly to the WTS-BS-4 USB Industrial Base Station in the customer’s computer and the WTS-BS-1-HA Handheld Digital Display for multiple transmitters. Get more information here: Landing Gear Joint Testing.

An aerospace company wants to test its new spacecraft assembly and design by testing its landing gear joints. They want to ensure no flaws in the gear shock absorber design and that it can handle the applied forces when the craft lands from a flight. Interface’s WTSLP Wireless Stainless Steel Load Pins can be installed and replace the normal pin joints. The spacecraft undergoes multiple drop tests at different heights, where the forces applied on the load pins are measured. The force results are transmitted wirelessly to the WTS-BS-4 USB Industrial Base Station in the customer’s computer and the WTS-BS-1-HA Handheld Digital Display for multiple transmitters. Get more information here: Landing Gear Joint Testing.

ATEX and IECEx Certified Load Pins for Liquid and Gas Production

Our team members designed and built a 1500kN Ex d (explosion-proof) load pin for an LNG project involving converting a semi-submersible drilling unit into a separation and boosting plant to receive production fluids and separate the gas from the liquids. Due to the environment where the load pin will operate, it must be suitable for use in Zone 1 hazardous areas. It was supplied with IECEx, ATEX certification, and a 3.1 material certificate for traceability. The load pin has an integral amplifier to provide a 4-20mA output, allowing direct connection via a 50-meter-long cable to an Ex-d-approved stainless steel display.

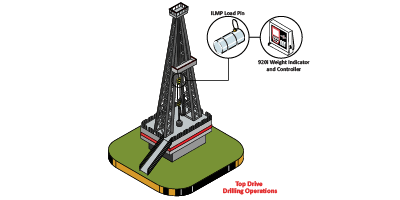

Interface ILMP Standard Stainless Steel Load Pin Monitors Top Drive Drill Operation

A top drive drill is used in the oil and gas industry. It’s a large, motorized drill that allows for the rotation of the drill string from the top of the drilling mast. Since the top drive is installed between the traveling block and the top drive, load pins are needed to suspend it more accurately and measure the weight of the bit. This means the rope reeving the hoist has no influence on the accuracy. Interface suggests using our ILMP Standard Stainless Steel Load Pin for this top drive application. The ILMP is installed at the traveling block, and during drilling operations, the ILMP will detect the force or weight of the top drive. Force results are monitored and displayed for the customer using the 920i Programmable Weight Indicator and Controller. Read the Top Drive application note.

A top drive drill is used in the oil and gas industry. It’s a large, motorized drill that allows for the rotation of the drill string from the top of the drilling mast. Since the top drive is installed between the traveling block and the top drive, load pins are needed to suspend it more accurately and measure the weight of the bit. This means the rope reeving the hoist has no influence on the accuracy. Interface suggests using our ILMP Standard Stainless Steel Load Pin for this top drive application. The ILMP is installed at the traveling block, and during drilling operations, the ILMP will detect the force or weight of the top drive. Force results are monitored and displayed for the customer using the 920i Programmable Weight Indicator and Controller. Read the Top Drive application note.

Food Production Equipment Uses Wireless Load Pins to Monitor Load Capacity

An equipment manufacturer required wireless load pins designed for food-handling machinery and equipment. These wireless sensors are rated at 42 tons and will be installed in the lateral support frame of a platform to monitor loading. The customer required bi-directional pins, with load readings available from upward and downward directions. The load pins were supplied with a 24-BSU base station, allowing viewing and logging data on demand via computer and a hand-held wireless display for instant viewing of load data.

ILMP Load Pins Monitor Tension on Fabric Winding Machine

In textile plants, fabric winding machines wind large fabric rolls together. A force measurement system is needed to continuously monitor the tension of the fabric as it winds and unwinds in the machine. The Interface ILMP Standard Stainless Steel Load Pin can replace the shaft holding the machine’s fabric roll. The load pins can measure the tension of the fabric while it winds or unwinds. Tension forces are measured using the BX8-AS BlueDAQ Series Data Acquisition System. Results can be monitored when connected to a computer using the BlueDAQ software. Check out Fabric Winding Machine and The Textile Industry’s Future Demands Force Measurement Solutions.

In textile plants, fabric winding machines wind large fabric rolls together. A force measurement system is needed to continuously monitor the tension of the fabric as it winds and unwinds in the machine. The Interface ILMP Standard Stainless Steel Load Pin can replace the shaft holding the machine’s fabric roll. The load pins can measure the tension of the fabric while it winds or unwinds. Tension forces are measured using the BX8-AS BlueDAQ Series Data Acquisition System. Results can be monitored when connected to a computer using the BlueDAQ software. Check out Fabric Winding Machine and The Textile Industry’s Future Demands Force Measurement Solutions.

Tractor Towing Assembly Needs Load Monitoring Solution Using Wireless Load Pins

An agricultural equipment manufacturer needs a tractor monitoring solution. So, we offered a 15-ton wireless load measuring pin to be installed in a tractor towing unit to provide load monitoring. The pin features an internal grease way with a helical grease dispersion groove to lubricate the load pin to minimize wear to the load pin and the towing assembly. An anti-rotation method was required, so the load pin was designed with four M10 lugs.

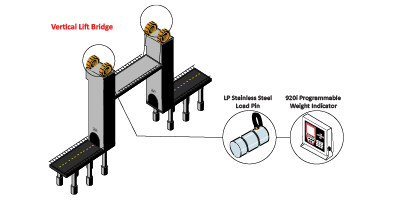

Interface LP Load Pins Monitor Bridge Lifts for Safety Monitoring

Road bridge lifts are specially constructed on roads or highways that intersect with water bodies such as rivers, canals, or harbors, allowing navigation to continue unimpeded. A force sensor system is needed to ensure the bridge’s structural integrity and safe operation. Interface suggests installing their LP Stainless Steel Load Pins within the pulleys of the bridge’s pulley system. When the bridge is lifted, the LPs will detect the force, and results are displayed for the customer using the 920i Programmable Weight Indicator and Controller. Read Road Bridge Lift Monitoring and our Bridge Lifting and Positioning App Note.

Road bridge lifts are specially constructed on roads or highways that intersect with water bodies such as rivers, canals, or harbors, allowing navigation to continue unimpeded. A force sensor system is needed to ensure the bridge’s structural integrity and safe operation. Interface suggests installing their LP Stainless Steel Load Pins within the pulleys of the bridge’s pulley system. When the bridge is lifted, the LPs will detect the force, and results are displayed for the customer using the 920i Programmable Weight Indicator and Controller. Read Road Bridge Lift Monitoring and our Bridge Lifting and Positioning App Note.

Hazardous Location Load Pins for Oil Well In-Line Tension Monitoring

We recently supplied an ATEX/IECEx hazardous area certified load pin for a global company that supplies safety equipment to various industry sectors. This load pin will be used to monitor in-line tension on an oil well, so it needs to be suitable for use in a potentially explosive atmosphere. The load pin is rated to 2000 lbf (900 kgs) and incorporates an integral amplifier for simple data downloading for logging and monitoring purposes.

INTERFACE’S EXPANDING LOAD PIN PRODUCT MODELS

Interface offers standard load pins with ratings between 1.1K lbf and 3.3M lbf (500 kgs to 1500 MT). We also provide custom-made load pins for applications requiring small-capacity load pins to retrofit into equipment or for use in large structural rigs for aircraft testing.

NEW! ILMP Standard Stainless Steel Load Pin 1.1K to 3,307K lbf (0.5MT to 1,500 MT): This standard Interface load measurement pin is designed for general use. They are versatile load pin load cells used in various lifting and weighing applications. Its simple design makes it ideal for cranes, winches, hoists, load shackles, and bearing blocks. Options include our Hazardous Environments ILMP Standard Stainless Steel Load Pin.

NEW! ILPW Standard Wireless Load Measuring Pin 1.1K to 3,307K lbf (500 kgs to 1,500 MT): This standard load pin is a popular option for a simple and versatile type of wireless load cell used in various applications, such as cranes, winches, hoists, load shackles, and bearing blocks.

LP Custom Stainless Steel Load Pin up to 3,000K lbf (up to 1,360 MT): Model LP Stainless Steel Load Pins are great for lifting applications involving short or long distances. This product can be amplified with 5VDC, 10VDC, or 4-20mA outputs. The load pins employ a full strain gage bridge as its measurement technology. Built to exacting standards, they are proof-loaded to 150% of the normal rated load and are temperature-compensated.

Hazardous Environments LP Custom Stainless Steel Load Pin up to 3,000K lbf (up to 1,360 MT): Interface supplies Ex d (explosion proof) and Ex I (intrinsically safe) load pins that are ATEX and IECEx certified. Intrinsically safe wireless versions are also available. Ranging in capacity to fit all environmental conditions and use cases, all our hazardous area load pins are supplied with complete environmental protection and calibration certification.

WTSLP Wireless Custom Stainless Steel Load Pin up to 3,000K lbf (up to 1,360 MT): The custom advanced load pin can transmit data wirelessly up to 600 (1,969 feet) meters in the distance (clear line of sight) to a handheld display or USB base station wireless instrumentation device. It utilizes low power consumption for extended battery life. It is configured and calibrated via PC using a base station and telemetry toolkit and is compatible with Interface WTS Wireless products. The load pin is robust and uses a lightweight housing. It is environmentally sealed to IP67. Also, we offer the Hazardous Environments WTSLP Wireless Custom Load Pins.

Load pins offer a robust and reliable solution for force measurement across a wide range of industries. From the demanding conditions of the maritime sector to the critical infrastructure of bridges, load pins provide essential data for safety, performance optimization, and system efficiency.

Interface, the leader in force measurement solutions, delivers high-quality, standard and custom-load pins tailored to your unique needs. Our expertise in design, manufacturing, and application sensor technologies ensures you have the right solution for your application. Ready to harness the power of load pins? Contact Interface today to discuss your project requirements.

Request a Quote from Interface, The World Leader of Force Measurement

ADDITIONAL RESOURCES

LP Stainless Steel Load Pin Configurator