Precision can make a difference in setting a record or winning a competition in esports and gaming. Esports are a form of digital video gaming in which individuals or teams compete in organized tournaments and leagues, primarily online.

These competitions revolve around various video game genres, requiring players to demonstrate high skill levels, strategy, and teamwork. Esports events are often streamed live and attract large audiences of spectators, blurring the lines between traditional sports and gaming.

Gaming hardware often takes a backseat to the spotlight enjoyed by the games themselves. However, the equipment must deliver exceptional accuracy, reliability, and responsiveness, from sim racing pedals to gaming controllers. This is where advanced measurement technologies like load cells, torque transducers, and force sensors come into play.

Hardware, including simulation monitors, gaming chairs, keyboards, controllers, and event display equipment, must withstand the demands of passionate and competitive gamers and their audiences. To ensure reliability and performance, each device undergoes extensive testing before gamers put equipment into play.

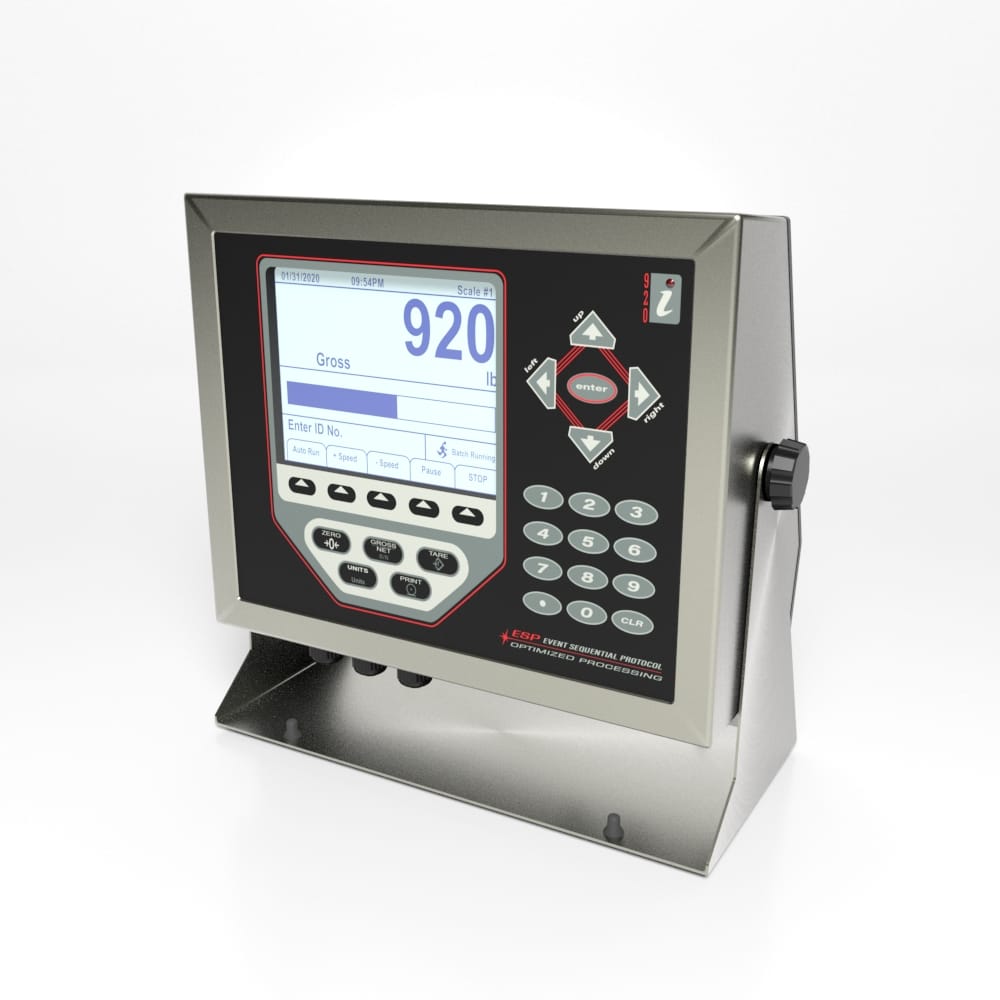

Interface offers a range of test and measurement solutions for gaming hardware manufacturers, including precision load cells in various sizes, wireless instrumentation, and digital output modules designed for seamless integration into simulation systems.

eSports and Gaming Applications Using Interface Test and Measurement Solutions

- VR Simulation Hardware Design and Testing

- Haptic Feedback System Testing

- Controller Testing and Optimization

- Gaming Brake Pedals

- Steering and Racing Wheel Force Feedback

- Keyboard and Mouse Testing, Keystroke Force, and Tactile Feedback

- Arena Display Rigging and Staging

- Button and Trigger Activation Force

- Haptic Feedback System Calibration

- Durability and Wear Testing

- Flight Simulator Controls

- VR Haptic Suits and Gloves

- Esports Training and User Performance Analysis

Load cells optimize esports and gaming hardware design and performance. They measure the force required for button presses, joystick movements, and keystrokes, ensuring responsiveness and comfort. This technology also helps calibrate haptic feedback systems in controllers and racing wheels for realistic gaming experiences. Furthermore, load cells are used to test the durability of gaming equipment and analyze player performance by measuring reaction time and pressure applied to controls. This data allows manufacturers to create high-quality, ergonomic hardware and helps players refine their techniques for a competitive edge.

For example, load cells play a critical role in gaming brake pedals. During the development and design phase, force measurement testing with load cells allows gaming pedal manufacturers to fine-tune the force required to slow or stop a virtual vehicle under different conditions. Additionally, load cells are valuable for assessing the durability and reliability of gaming components.

Gaming arena facilities use load cell technology in support infrastructure and visualization screens to bring virtual reality and esports to life. These technologies are used in innovative venue designs and one-of-a-kind virtual experiences.

Interface offers a range of test and measurement solutions for gaming hardware manufacturers, including precision load cells in various sizes, wireless instrumentation, and digital output modules designed for seamless integration into simulation systems.

Water Bottle Dispensing and Weighing

Water Bottle Dispensing and Weighing

Smart Food Packaging Uses Force Measurement

/in Blog /by Jamie GlassInterface force measurement technologies are helping to transform the food packaging industry with greater precision and reduced waste. Interface offers sensor solutions to automate and regulate every packaging stage, from rigorous packaging material tests to precise force measurements for filling, sealing, and distributing food products.

Precision Prototyping Uses Force Measurement for Design Validation

/in Blog /by Jamie GlassInterface load cells, torque transducers, and multi-axis sensors equip engineers with essential data for design validation and optimization for precise prototyping. Whether for testing alone or integration, both scenarios for sensors measuring physical parameters like force, torque, and weight provide insights into the prototype’s performance and behavior under various conditions. Industries use proof-of-concepts, production prototypes, and functional prototypes that require precise measurements to validate the final design.

Interface Top Industry and Application Insights of 2024

/in Blog /by Jamie GlassExplore Interface’s top industry solutions and applications using force measurement products. Discover medical, aerospace, automation, automotive, energy, and other industry test and measurement applications. Find inspiration and answers for your specific needs using Interface load cells, torque transducers, and instrumentation.

Fun Facts About Force Measurement to Wrap Up 2024

/in Blog /by Jamie GlassInterface fun facts demonstrate how force measurement constantly evolves and contributes to breakthroughs in various fields, from measuring rocket thrust to monitoring athlete’s performance. It’s a testament to the ingenuity of engineers and scientists who continue to find new and innovative ways to utilize this fundamental measurement principle.

Integrated Measurement Solutions Elevate Design and Enhance Functionality

/in Blog /by Jamie GlassInterface, a pioneer in load cell design, supports innovation by offering integrated measurement solutions that ensure the safety and reliability of machines, products, and processes in sectors including aerospace, energy, medical and healthcare, automotive, manufacturing, and industrial automation. Our sensor technologies are seamlessly integrated into diverse products and machines, from lifting equipment to consumer goods. This adaptability ensures that our solutions can be tailored to your unique requirements.

Load Cell Connection to USB Instrumentation Advances Measurement Applications

/in Blog /by Jamie GlassInterface offers USB instrumentation solution to connect load cells to digital devices. Using USB, load cells can seamlessly integrate with various instrumentation, such as computers, data loggers, and programmable logic controllers (PLCs), through a standard USB interface and compatible software. This digital connectivity eliminates the need for complex analog-to-digital converters and streamlines the data acquisition process. Learn about products, advantages, challenges and tips for using USB instrumentation.

Safeguarding Products and Packaging Integrity Using Load Cells

/in Blog /by Jamie GlassInterface load cells provide valuable measurement data for packaging processes and equipment. They are used in material testing, package drop tests, quality control, delivery equipment, and conveyor belts. By incorporating load cells into packaging processes, product manufacturers and packaging industry suppliers can gain valuable insights into testing the stresses and strains a package encounters. Load cells can provide substantial cost savings, enhanced production efficiency, faster time to market, and improved product safety.

Measuring the Potential of IoT Wearables Using Load Cell Technology

/in Blog /by Jamie GlassInterface load cells provide valuable measurement data in real-time to product engineers and users of IoT wearables. Load cells are popular in designing, prototyping, testing, and using wearable IoT products, including shoes, sports gear, prosthetics, watches, and gaming headsets. They offer a highly accurate and reliable way to measure force, pressure, and weight. Our measurement devices are being designed into wearables such as smart clothing and augmented reality equipment, including headsets and fitness equipment for precision measurement during use.

What is Proof Testing and Why Does it Matter?

/in Blog /by Jamie GlassInterface load cells and data acquisition systems are used for proof testing, which determines the strength and integrity of a test subject by applying a controlled, measured load to it. What is proof testing? Learn the steps of proof testing for stress, fatigue, and materials. It is frequently used by industries such as construction, natural resources, infrastructure, heavy machinery, and manufacturing to verify the strong point and durability of objects and structures.

Year in Review of Top Interface Solutions and Applications

/in Blog /by Jamie GlassInterface is at the forefront of innovative use cases and applications, providing quality devices worldwide to gather precision measurements. Interface unveils the top industry solutions, product use cases and applications that define force measurement in 2023.