Autonomous robot dogs are highly advanced machines that are transforming the manufacturing industry. These specialized robotic innovations are being used to tackle complex challenges in production, maintenance, and logistics.

These versatile machines are designed to navigate intricate environments. They replicate the movements of real dogs, utilizing state-of-the-art sensors, cameras, and software, which enables them to perform tasks that require mobility, dexterity, and decision-making in dynamic conditions.

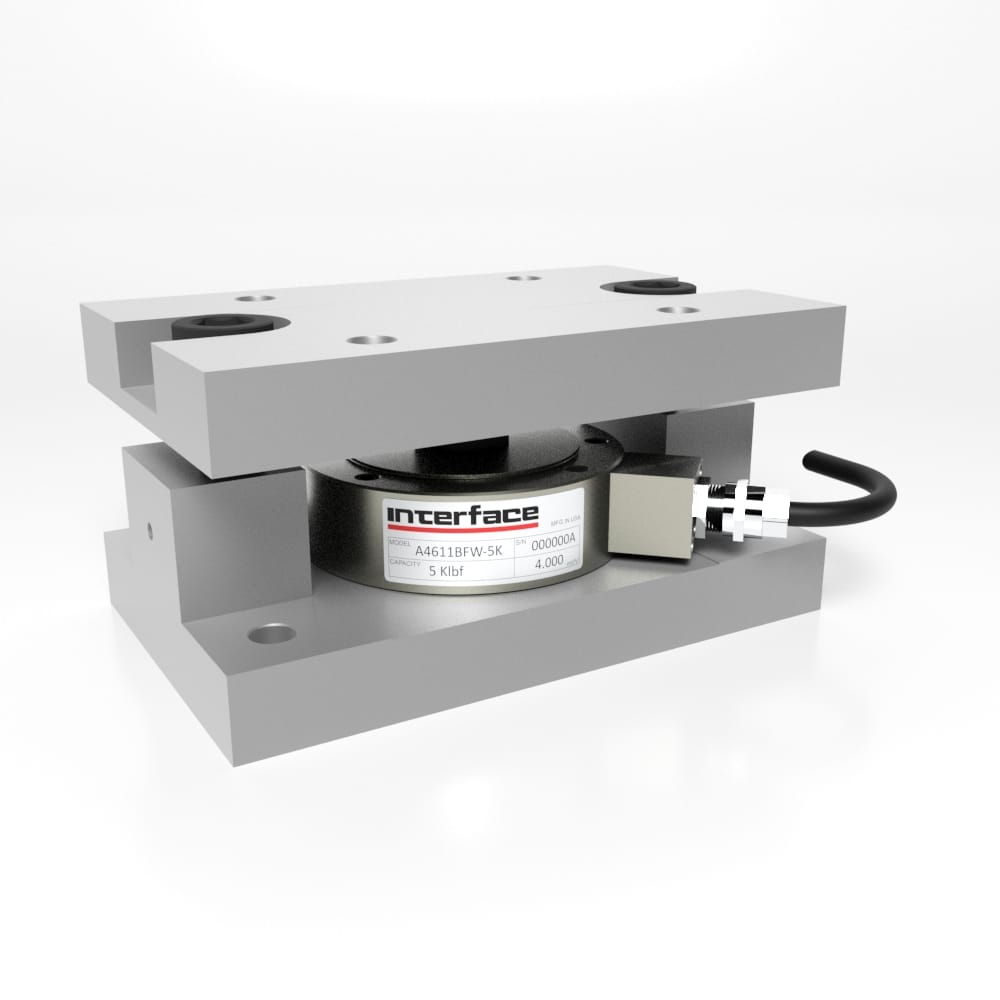

Interface products aid in the development and testing of robotic dogs, providing precise measurements for performance analysis.

By integrating Interface’s advanced force measurement technologies into robot dogs, manufacturers can achieve higher precision and functionality, enhancing the overall performance of their robots.

Types of Interface Products Used in Robotic Dogs

- Load cell force data can help to adjust grip strength, ensuring they apply just the right amount of force without damaging either the item or themselves.

- Load button load cells integrated into the robot’s feet measure ground contact forces, which are crucial for assessing stability and balance.

- Multi-axis sensors capture complex force and torque data during dynamic movements, aiding in locomotion optimization and stress analysis.

- Wireless instruments enable real-time data transmission, facilitating field testing and performance monitoring.

- Mini Load Cells provide data to autonomously adjust their movement and force application when lifting or moving a component.

These technologies collectively contribute to evaluating stability, analyzing movements, assessing performance across terrains, and ensuring the robot’s long-term durability.

Robotics Dogs Use Cases in Manufacturing

Robotic dogs are already being deployed in manufacturing environments for various tasks, including quality monitoring, inventory management, security, and safety checks. The following highlights the use of robotic dogs in various manufacturing functions.

#1 Inspection and Monitoring: By utilizing Interface’s force sensors, robot dogs can be programmed to measure the forces acting on machinery or products, allowing them to detect subtle changes in force or pressure that may indicate potential issues.

#2 Object and Material Handling: Force sensors can be used to accurately measure the amount of force applied by the robot dog when it handles or manipulates objects. This ensures that delicate materials are not damaged and heavy items are handled safely.

#3 Predictive and Routine Maintenance: By integrating load cells and force sensors, robot dogs can collect valuable data that can be used for predictive maintenance. For instance, the sensors can monitor the performance of various machines in the facility, recording changes in force or load that may indicate wear and tear. This data can be analyzed to predict when maintenance is needed, preventing equipment failure and reducing costly downtime.

#4 Security Patrols: Robotic dogs provide continuous, mobile surveillance in diverse environments, enabling them to detect anomalies and navigate challenging terrains, thereby increasing security efficiency. They can patrol hazardous areas, reducing human risk, and are used in military, industrial, and private security settings for persistent monitoring.

#5 Hazardous Environments: Robotic dogs excel in hazardous environments by remotely navigating and inspecting dangerous areas, minimizing human risk. Equipped with sensors and cameras, they collect vital data from facilities, thereby enhancing safety and enabling informed decisions without requiring direct human exposure.

The combination of autonomous robot dogs and Interface’s advanced load cells and force sensors represents a powerful leap forward in the manufacturing industry. As the world continues to move toward more automated and intelligent manufacturing processes, the role of autonomous robot dogs will become increasingly critical, with Interface sensors playing a key role in ensuring precision and reliability.

ForceLeaders Summit Dallas 2025

/in Trade Show /by Jamie GlassInterface ForceLeaders Summit Dallas happens on April 15, 2025. The force measurement technical workshops highlight load cells, torque testing, multi-axis sensors, and data acquisition instrumentation. Interface and T&M engineers and experts for best practices, testing tips, and experiences using load cells, torque transducers, multi-axis sensors, and advanced instrumentation. Register to join the technical conversation. Seating is limited

The Force Behind the Future of Humanoid Robotics

/in Blog /by Jamie GlassInterface provides force measurement sensors and instrumentation for humanoid robot design, testing, and performance monitoring. Humanoid testing of the human-like movements, balance, manipulation, and interactions require accurate force measurement using load cells, torque transducers, and multi-axis sensors. Interface is dedicated to providing high-quality sensor solutions for all types of robotics.

Selecting the Right Indicator for Test and Measurement Applications

/in Blog /by Jamie GlassInterface offers a diverse range of indicators for precise load cell, torque, and weighing applications. Ensure accurate force measurement by reviewing our top 10 selection criteria and explore Interface’s indicator instrumentation solutions.

Precision Prototyping Uses Force Measurement for Design Validation

/in Blog /by Jamie GlassInterface load cells, torque transducers, and multi-axis sensors equip engineers with essential data for design validation and optimization for precise prototyping. Whether for testing alone or integration, both scenarios for sensors measuring physical parameters like force, torque, and weight provide insights into the prototype’s performance and behavior under various conditions. Industries use proof-of-concepts, production prototypes, and functional prototypes that require precise measurements to validate the final design.

Interface Top Industry and Application Insights of 2024

/in Blog /by Jamie GlassExplore Interface’s top industry solutions and applications using force measurement products. Discover medical, aerospace, automation, automotive, energy, and other industry test and measurement applications. Find inspiration and answers for your specific needs using Interface load cells, torque transducers, and instrumentation.

The Interplay of EduRobots and Accurate Measurement

/in Blog /by Jamie GlassAs technology evolves, educational tools increasingly incorporate advanced robotics to enhance learning experiences at all levels. Educational robots are a class of intelligent humanoid robots representing the forefront of innovation. These EduRobots merge cutting-edge artificial intelligence (AI) with mechanical engineering […]

How Sensor Technologies Help Build Better Highways, Bridges, and Roadways

/in Blog /by Jamie GlassInterface load cells, load pins, instrumentation, multi-axis sensors, and torque transducers are top choices for those engaged in highway, roadway, and bridge infrastructure projects and testing. Sensors commonly measure the hardware used for transportation infrastructure products and structures. Driven by increasing industrial automation, rising demand for precision measurement, and stringent safety regulations, force, torque, and weighing solutions are necessary for ensuring safety, optimizing performance, and managing costs throughout the infrastructure lifecycle.

Why Use a Limit Switch in Force Measurement?

/in Blog /by Jamie GlassLimit switches can prevent equipment damage and enhance accuracy in force measurement. Interface TechTalk defines a limit switch and how these safety devices protect load cells, prevent overloads, and improve control in testing. Discover use cases for limit switches, including in aerospace testing, cranes, industrial automation and lifting heavy objects.

Transformational Warehouse Automation Relies on Precision Measurement

/in Blog /by Jamie GlassInterface force and torque sensors are advancing warehouse automation and optimization by providing critical measurement data for tasks ranging from robotic arm control to preventing overload in material handling equipment. Whether designing a humanoid package handler or establishing weight restrictions in mobility machines, accurate measurement is crucial for safety, efficiency, and cost-effectiveness. Learn more about Interface warehouse automation measurement solutions including load cells, torque transducers, load pins, multi-axis sensors and wireless instrumentation.

Retrofitting Factories with Measurement Solutions

/in Blog /by Jamie GlassInterface force, torque, and weight measurement solutions for retrofitting factories and modernizing manufacturing can significantly improve operations, efficiency, productivity, safety, and sustainability. Load cells, multi-axis sesnors and load pins can upgrade existing machines and equipment to provide sensor data for predictive maintenance, quality control and improving durabiity.