Autonomous robot dogs are highly advanced machines that are transforming the manufacturing industry. These specialized robotic innovations are being used to tackle complex challenges in production, maintenance, and logistics.

These versatile machines are designed to navigate intricate environments. They replicate the movements of real dogs, utilizing state-of-the-art sensors, cameras, and software, which enables them to perform tasks that require mobility, dexterity, and decision-making in dynamic conditions.

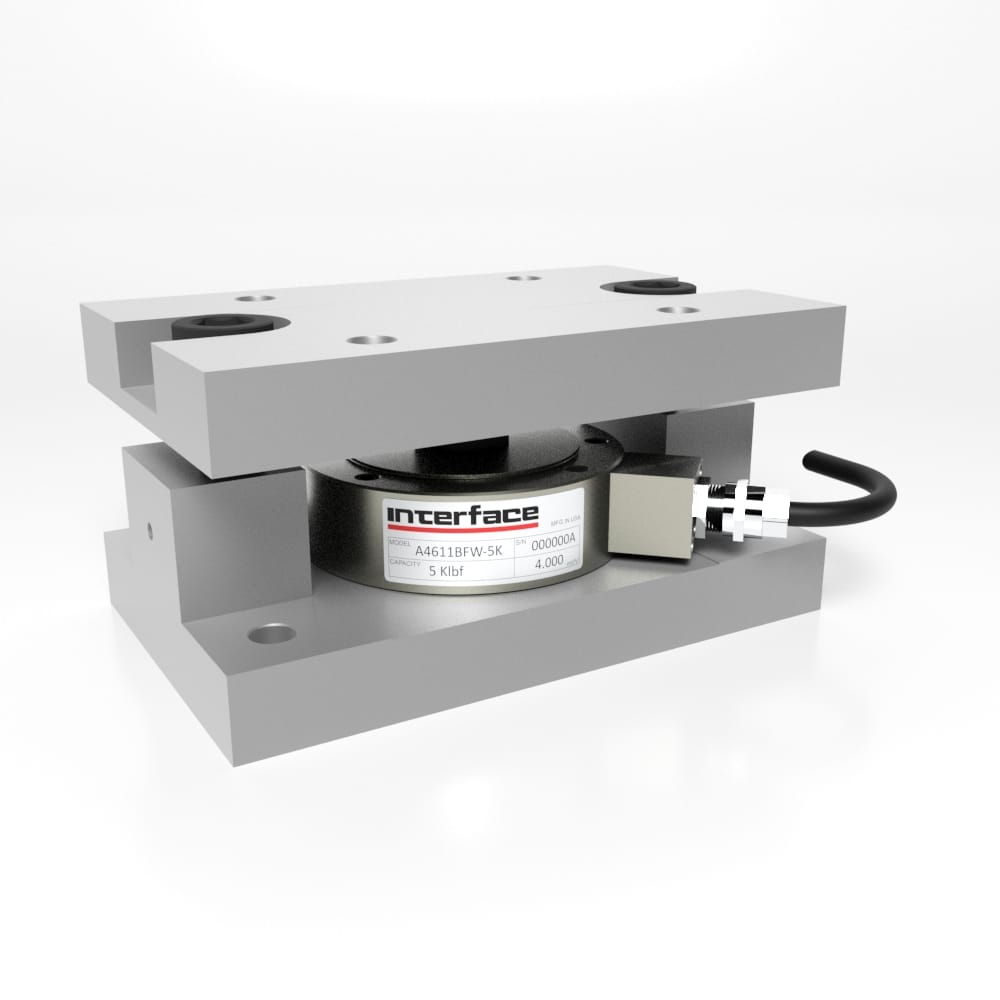

Interface products aid in the development and testing of robotic dogs, providing precise measurements for performance analysis.

By integrating Interface’s advanced force measurement technologies into robot dogs, manufacturers can achieve higher precision and functionality, enhancing the overall performance of their robots.

Types of Interface Products Used in Robotic Dogs

- Load cell force data can help to adjust grip strength, ensuring they apply just the right amount of force without damaging either the item or themselves.

- Load button load cells integrated into the robot’s feet measure ground contact forces, which are crucial for assessing stability and balance.

- Multi-axis sensors capture complex force and torque data during dynamic movements, aiding in locomotion optimization and stress analysis.

- Wireless instruments enable real-time data transmission, facilitating field testing and performance monitoring.

- Mini Load Cells provide data to autonomously adjust their movement and force application when lifting or moving a component.

These technologies collectively contribute to evaluating stability, analyzing movements, assessing performance across terrains, and ensuring the robot’s long-term durability.

Robotics Dogs Use Cases in Manufacturing

Robotic dogs are already being deployed in manufacturing environments for various tasks, including quality monitoring, inventory management, security, and safety checks. The following highlights the use of robotic dogs in various manufacturing functions.

#1 Inspection and Monitoring: By utilizing Interface’s force sensors, robot dogs can be programmed to measure the forces acting on machinery or products, allowing them to detect subtle changes in force or pressure that may indicate potential issues.

#2 Object and Material Handling: Force sensors can be used to accurately measure the amount of force applied by the robot dog when it handles or manipulates objects. This ensures that delicate materials are not damaged and heavy items are handled safely.

#3 Predictive and Routine Maintenance: By integrating load cells and force sensors, robot dogs can collect valuable data that can be used for predictive maintenance. For instance, the sensors can monitor the performance of various machines in the facility, recording changes in force or load that may indicate wear and tear. This data can be analyzed to predict when maintenance is needed, preventing equipment failure and reducing costly downtime.

#4 Security Patrols: Robotic dogs provide continuous, mobile surveillance in diverse environments, enabling them to detect anomalies and navigate challenging terrains, thereby increasing security efficiency. They can patrol hazardous areas, reducing human risk, and are used in military, industrial, and private security settings for persistent monitoring.

#5 Hazardous Environments: Robotic dogs excel in hazardous environments by remotely navigating and inspecting dangerous areas, minimizing human risk. Equipped with sensors and cameras, they collect vital data from facilities, thereby enhancing safety and enabling informed decisions without requiring direct human exposure.

The combination of autonomous robot dogs and Interface’s advanced load cells and force sensors represents a powerful leap forward in the manufacturing industry. As the world continues to move toward more automated and intelligent manufacturing processes, the role of autonomous robot dogs will become increasingly critical, with Interface sensors playing a key role in ensuring precision and reliability.

Sensing the World of Load Cells and Accelerometers

/in Blog /by Jamie GlassLoad cells and accelerometers are sensors with two different purposes in test and measurement. Interface load cells are perfect for measuring static forces with high precision. An accelerometer excels in detecting dynamic motion, vibrations, and impact. There are use cases for load cells and accelerometers to work together in a single advanced system. Interface can provide the force and measurement solutions for systems that measure force, weight, torque, acceleration, motion, and vibration.

Integrated Measurement Solutions Elevate Design and Enhance Functionality

/in Blog /by Jamie GlassInterface, a pioneer in load cell design, supports innovation by offering integrated measurement solutions that ensure the safety and reliability of machines, products, and processes in sectors including aerospace, energy, medical and healthcare, automotive, manufacturing, and industrial automation. Our sensor technologies are seamlessly integrated into diverse products and machines, from lifting equipment to consumer goods. This adaptability ensures that our solutions can be tailored to your unique requirements.

Load Cell Connection to USB Instrumentation Advances Measurement Applications

/in Blog /by Jamie GlassInterface offers USB instrumentation solution to connect load cells to digital devices. Using USB, load cells can seamlessly integrate with various instrumentation, such as computers, data loggers, and programmable logic controllers (PLCs), through a standard USB interface and compatible software. This digital connectivity eliminates the need for complex analog-to-digital converters and streamlines the data acquisition process. Learn about products, advantages, challenges and tips for using USB instrumentation.

Practical Engineering Tips to Design In Sensors

/in Blog /by Jamie GlassInterface offers engineering tips to create intelligent solutions that adapt, optimize, and safeguard operations when designing in load cells, torque transducers, and multi-axis sensors into equipment, products, and components. The first step is define what you are trying to solve and why you need a measurement sensor in your design. Review 0 helpful questions to guide you in the discovery and solution definition stage.

Measurement Solutions Advance Industrial IoT Success

/in Blog /by Jamie GlassInterface provides high-accuracy measurement solutions for Industrial IoT. Our Wireless Telemetry System (WTS) components drive adoption and innovation in IIoT, from cobot design to smart pallet inventory controls. Load cells, torque transducers, instrumentation, and DAQ systems evaluate force, torque, and weighing data to optimize IIoT in manufacturing, energy, agriculture, and other sectors.

Interface Sensors Steer Construction Machinery Performance

/in Blog /by Jamie GlassInterface measurement solutions provide critical force, torque, and weight data for construction machinery. Interface load cells, torque transducers, load pins, tension load links, and load shackles, contribute to the efficient functioning of these heavy-duty mechanical pieces of equipment. Interface products are used for construction machinery safety protocols, heavy equipment testing, overload monitoring, machine maintenance, and accurate regulatory and compliance data.

How Force Measurement is Driving AMR Innovation

/in Blog /by Jamie GlassInterface force measurement solutions are instrumental across the entire AMR lifecycle, from design and testing to manufacturing and deployment. Autonomous Mobile Robots use data from load cells and torque transducers for measuring performance, machine learning, and safe integration into factories and warehouses. As AMRs find new use cases, Interface sensor technologies help advance innovation through design, testing, prototyping, and manufacturing.

High Accuracy Load Cell Solutions for Trustworthy Scales

/in Blog /by Jamie GlassInterface supplies precision load cells for advanced scale applications. Accuracy is the primary advantage of using Interface load cells over traditional mechanical scales. The strain gage technology used in these sensors ensures a precise measurement of weight, making them a reliable choice for precision scale applications. Engineers use load cell-based weighing systems to advance the precision and quality of scale measurement. Interface load cells are integrated into scale equipment for continuous weight monitoring and play crucial roles in automation, batching, check weighing, process control, and sample testing.

Recap of Precision Machine Building and Automation Webinar

/in Blog /by Jamie GlassInterface’s webinar, Powering Up Precision Machine Building and Automation explores the essential role of sensor technology in today’s industrial landscape. Learn about load cells, torque transducers, multi-axis sensors and instrumenation used testing machines, robotics, IIoT and automation. The recorded event captures key trends, tips, and applications valuable to machine builders, engineers, testing labs, and manufacturers.

The Marvels of Interface Mini Load Cells

/in Blog /by Jamie GlassInterface Mini Load Cells are engineered for use in applications that require a light touch, are lightweight, or require less space. The Interface miniature sensor line offers not just small in physical size load cells and torque transducers, they also have a range to test minimal forces with extremely high accuracy. They are making a big impact in industrial automation, aerospace, automotive and medical device OEM products.