Interface sensor technologies and solutions find extensive usage in the global construction sector for monitoring and controlling the loads encountered during the construction projects. From bridges and dams to high-rise buildings and tunnels, measurement devices and instrumentation are utilized by civil engineers, heavy equipment manufacturers, material engineers, and test labs to accurately measure and test weight, force, and torque across a variety of use cases.

The massive global construction industry, estimated to be nearly $13T in spending, is broad and diverse in use of measurement solutions. From single building tools to heavy machines used to move concrete slabs, measurement is fundamental in construction design and use for projects, tools and heavy equipment.

Interface products for test and measurement in this diverse industry are used in:

- Residential Construction

- Commercial Construction

- Infrastructure Construction

- Industrial Construction

- Civil Engineering Projects and Construction

- Mining and Tunneling

- Environmental Remediation

- Specialty Projects

- Heavy Equipment Manufacturing

- Transportation and Vehicle OEMs

- Cranes and Lifting Equipment

Interface load cells offer precise measurements of applied forces, furnishing essential data regarding the structural response under various load circumstances. This data plays a critical role in evaluating structural integrity, detecting potential vulnerabilities, and optimizing design to guarantee the safety and dependability of infrastructure.

Products we commonly supply to construction industry participants include:

- Load Cells

- Miniature Load Cells

- Torque Transducers

- Scales

- Multi-Axis Sensors

- Load Pins, Load Shackles and Tension Links

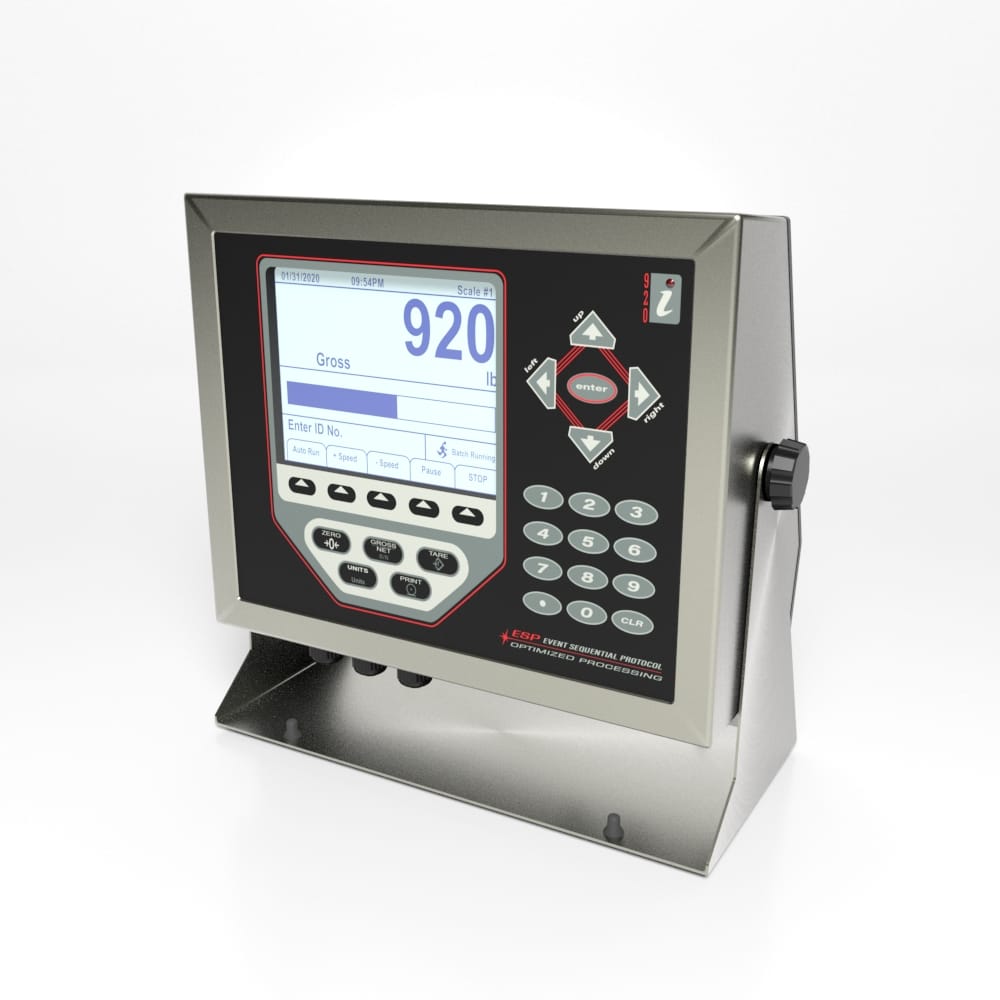

- Instrumentation

- Digital, Wireless and Bluetooth Solutions

- Custom Solutions

Load cells also are commonly used in construction equipment including cranes, hoists, and lifts. By incorporating Interface’s load cells into these machines, construction operators can reliably ascertain the loads being lifted or moved, ensuring compliance with secure operational thresholds.

By providing real-time load data, Interface’s load cells enable engineers and construction industry players to make informed decisions regarding the structural design, material selection, and load capacity of different machines and equipment. Torque transducers assist in evaluating and monitoring static and rotary movements of objects like motors and tools. Instrumentation is used to gather the data from measurements, which can influence design and be used as embedded technologies to give real-time feedback in use, just as in cranes and lifts.

Safety is of the utmost importance in the construction sector. Severe failures in equipment can be dangerous to machine operators, and protection and safety for users can be used through the use of force sensor technologies with Interface’s precision load cells, torque transducers, load pins, tension links and load shackles.

Applications of Force Measurement Products Used in the Construction Industry:

Bridge Construction: Load cells are employed in bridge construction to monitor the loads experienced by different components such as piers, beams, and cables. They help ensure that the bridge can handle the anticipated weight and forces and provide valuable data for load testing and structural analysis. Bridges also use sensors to provide ongoing monitoring of environmental changes, as noted in our case study Monitoring Seismic Force of a Suspension Bridge.

High-Rise Building Construction: For structural support, load cells are used during the construction of tall buildings to measure the loads exerted on structural elements like columns, slabs, and foundation systems. They assist in evaluating the structural integrity, optimizing design, and determining load distribution for safe and stable construction.

Crane and Heavy Lifting Operations: Sensors, including load cells, are frequently integrated into cranes, hoists, and lifting equipment to accurately measure the loads being lifted. This enables operators to ensure that the weight being lifted is within safe operating limits, preventing overloading and potential accidents.

Foundation Load Testing: Utilized in foundation load testing, load cells help to assess the bearing capacity and settlement behavior of foundations. They help determine the maximum loads that can be supported by the foundation, ensuring its stability and preventing settlement-related issues.

Structural Monitoring: Structural and civil engineers use load cells for ongoing monitoring of loads in structures such as tunnels, dams, and retaining walls. They provide continuous data on the loads acting on these structures, helping engineers assess their performance, detect any excessive stress or deformations, and ensure their long-term safety.

Material Testing: The materials used in construction range from steel to wood, even fabricated materials like rubber and foam. Load cells are employed in material testing laboratories to measure the strength and mechanical properties of construction materials such as concrete, steel, and timber. They play a critical role in conducting compression, tension, and bending tests, providing accurate load measurements for material performance evaluation.

Construction Equipment Calibration: As with all critical sensors, load cells are needed to calibrate and verify the accuracy of construction equipment, including weighing scales, hydraulic systems, and lifting devices. This ensures that the equipment operates correctly and delivers precise load measurements during construction activities. Utilizing Interface calibration grade load cells and systems is highly recommended for this type of use.

Construction Brochure

Aerial Lift Overload Control

Aerial Lift Overload Control

How Sensor Technologies Help Build Better Highways, Bridges, and Roadways

/in Blog /by Jamie GlassInterface load cells, load pins, instrumentation, multi-axis sensors, and torque transducers are top choices for those engaged in highway, roadway, and bridge infrastructure projects and testing. Sensors commonly measure the hardware used for transportation infrastructure products and structures. Driven by increasing industrial automation, rising demand for precision measurement, and stringent safety regulations, force, torque, and weighing solutions are necessary for ensuring safety, optimizing performance, and managing costs throughout the infrastructure lifecycle.

Advanced Force Measurement Solutions for Water Infrastructure

/in Blog /by Jamie GlassInterface offers a range of force measurement products indispensable in water management. Interface’s force measurement solutions provide force, torque, and weight data for managing aquatic systems’ safety, efficiency, and sustainability. From monitoring water levels to optimizing pump performance and preventing leaks, these solutions provide the data and insights needed to make informed decisions and keep our water resources flowing smoothly.

Force Sensors in Heavy Machinery Boost Safety and Performance

/in Blog /by Jamie GlassInterface load cells, torque transducers and multi-axis sensors help prevent heavy machinery overloading, equipment failure, and accidents by providing real-time data on forces, loads, and structural integrity. Accurate measurements enable optimization of machine performance, fuel consumption, and material usage. Continuous monitoring of forces and loads allows for early detection of potential issues, minimizing downtime and repair costs in manufacturing, infrastructure, construction, agriculture, energy, natural resources and other industries.

Measurement Solutions Advance Industrial IoT Success

/in Blog /by Jamie GlassInterface provides high-accuracy measurement solutions for Industrial IoT. Our Wireless Telemetry System (WTS) components drive adoption and innovation in IIoT, from cobot design to smart pallet inventory controls. Load cells, torque transducers, instrumentation, and DAQ systems evaluate force, torque, and weighing data to optimize IIoT in manufacturing, energy, agriculture, and other sectors.

Interface Sensors Steer Construction Machinery Performance

/in Blog /by Jamie GlassInterface measurement solutions provide critical force, torque, and weight data for construction machinery. Interface load cells, torque transducers, load pins, tension load links, and load shackles, contribute to the efficient functioning of these heavy-duty mechanical pieces of equipment. Interface products are used for construction machinery safety protocols, heavy equipment testing, overload monitoring, machine maintenance, and accurate regulatory and compliance data.

Silo and Tank Measurement Solutions

/in Blog /by Jamie GlassInterface provides testing sensors, weighing devices, and force measurement solutions used for tanks, silos, vessels, and industrial storage containers in several industries, including agriculture, infrastructure, manufacturing, natural resource management, and energy. Load cells are invaluable tools for silos and tanks, providing accurate and reliable force and weight measurements. The benefits of implementing precision measurement systems for testing and monitoring include improved accuracy, real-time data, reduced waste, enhanced safety, and cost savings.

Measurement Sensors Optimize Underground Tunneling and Boring

/in Blog /by Jamie GlassInterface sensor technologies are critical to tunnel boring operations. Interface load cells can be strategically embedded within tunnel boring machines (TBMs) and accurately measure the forces exerted during excavation. Torque transducers can measure reaction or rotational forces on equipment components to ensure tools and machines operate properly. Using measurement sensors, machines can monitor parameters like torque, thrust, force, and weight to provide real-time feedback to operators.

Force Makes the Circular Economy Go Around

/in Blog /by Jamie GlassInterface load cells and instrumentation are used in different facilities and resource manufacturing processes within the circular economy. Our sensor technologies help to measure and monitor forces, loads, and weight within the tools, robotics, and machinery used to optimize resources. Our sensors are also commonly used to test new products for material strength, fatigue lifecycle, quality, and function.

What is Proof Testing and Why Does it Matter?

/in Blog /by Jamie GlassInterface load cells and data acquisition systems are used for proof testing, which determines the strength and integrity of a test subject by applying a controlled, measured load to it. What is proof testing? Learn the steps of proof testing for stress, fatigue, and materials. It is frequently used by industries such as construction, natural resources, infrastructure, heavy machinery, and manufacturing to verify the strong point and durability of objects and structures.

A Great Force for Crane and Hoist Solutions

/in Blog /by Jamie GlassLCM-made products in Interface’s 35,000-plus catalog include Load Pins, Tension Links, and Shackles. This includes options for standard products, engineered-to-order, completely custom, ATEX, submersibles, and wireless solutions. Interface and recently acquired LCM Systems offer our customers powerful and diverse measurement devices for hoisting, winching, lifting, subsea, infrastructure, and industrial manufacturing applications.