Sensor technology is transforming safety and efficiency in cranes and heavy-lifting equipment. Interface load cells, load pins, shackles, and tension load links are integrated directly into the machinery to monitor forces during operation, provide real-time data on load status, and ensure safe operation.

The measurement data obtained from the measurement devices is crucial for preventing overloads, optimizing load distribution, and enhancing safety. By accurately measuring the weight and forces exerted during lifting, these sensors help operators stay within safe operational limits, preventing accidents and equipment failure.

These advanced measurement solutions are used across various applications, from construction and shipping to manufacturing and material handling. By providing precise, real-time data on load status, this technology empowers operators to make informed decisions, maximize productivity, and ensure the longevity of their equipment.

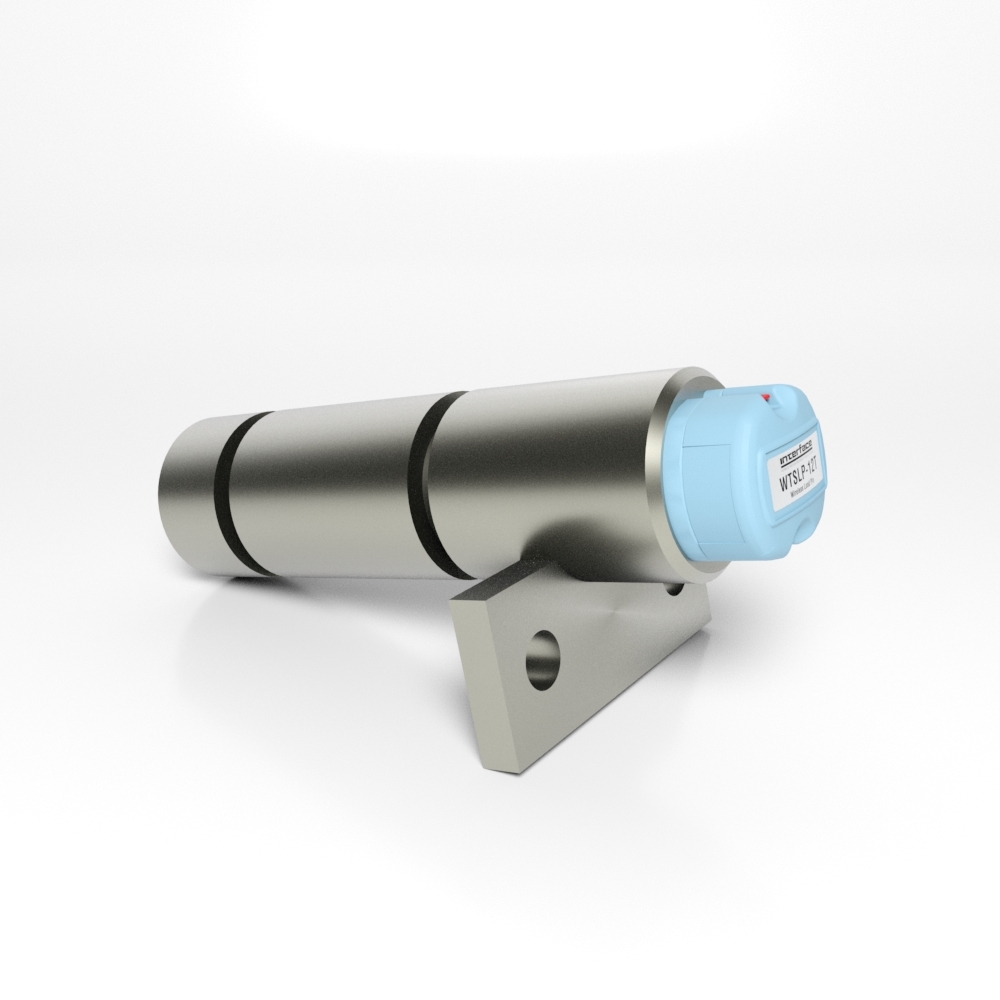

Interface Products for Crane Applications

Load cells play a crucial role in various crane types, from the towering giants of construction sites to the simple lifters in workshops. By accurately measuring the forces exerted during lifting operations, these sensors prevent overloads, optimize load distribution, enhance safety, and prevent machinery failure.

Here’s how this technology is applied across different crane types:

- Tower Cranes: Maintain stability and prevent overloads in high-rise construction.

- Mobile Cranes: Monitor weight and prevent tipping, especially on uneven terrain.

- Overhead Cranes: Ensure precise load handling and positioning in industrial settings.

- Marine Cranes: Account for vessel movement and maintain load stability during ship-to-shore operations.

- Gantry Cranes: Prevent overload and ensure stability when moving heavy items across their span.

- Smaller Cranes: Ensure safe lifting within capacity in workshops and service trucks.

Whether a massive gantry crane hoists shipping containers or a service truck crane lifts equipment, integrated load cells provide crucial real-time data, enabling operators to work safely and efficiently within the crane’s limits. This technology is essential for preventing accidents, optimizing performance, and extending the lifespan of heavy machinery.

Interface crane solutions are used in various industries and settings, including construction sites, warehouses, manufacturing facilities, transportation, healthcare facilities, maritime docks, aircraft testing and assembly, and infrastructure projects.

At Interface, safety and the well-being of others in environments using cranes are of the utmost importance due to the high risks associated with heavy loads, heights, and moving parts. The use of our load monitoring devices, such as load cells, tension links, load pins, or load shackles, is critical to ensuring efficient and safe crane operations.

Force Sensors in Heavy Machinery Boost Safety and Performance

/in Blog /by Jamie GlassInterface load cells, torque transducers and multi-axis sensors help prevent heavy machinery overloading, equipment failure, and accidents by providing real-time data on forces, loads, and structural integrity. Accurate measurements enable optimization of machine performance, fuel consumption, and material usage. Continuous monitoring of forces and loads allows for early detection of potential issues, minimizing downtime and repair costs in manufacturing, infrastructure, construction, agriculture, energy, natural resources and other industries.

Practical Engineering Tips to Design In Sensors

/in Blog /by Jamie GlassInterface offers engineering tips to create intelligent solutions that adapt, optimize, and safeguard operations when designing in load cells, torque transducers, and multi-axis sensors into equipment, products, and components. The first step is define what you are trying to solve and why you need a measurement sensor in your design. Review 0 helpful questions to guide you in the discovery and solution definition stage.

Showcasing Load Pin Versatility and Adaptation

/in Blog /by Jamie GlassInterface Load Pin measurement devices provide real-time force and weighing data for performance monitoring, equipment quality control, operational support, and product safety. These load pins are used in energy, agriculture, manufacturing, aerospace, infrastructure and manufacturing industriy applications. Interface Load Pins are machined from high-tensile stainless steel and are suitable for all settings, including exposed environments such as seawater. They are used in heavy machinery in industrial factories and submersible energy generators in the ocean.

Interface Sensors Steer Construction Machinery Performance

/in Blog /by Jamie GlassInterface measurement solutions provide critical force, torque, and weight data for construction machinery. Interface load cells, torque transducers, load pins, tension load links, and load shackles, contribute to the efficient functioning of these heavy-duty mechanical pieces of equipment. Interface products are used for construction machinery safety protocols, heavy equipment testing, overload monitoring, machine maintenance, and accurate regulatory and compliance data.

The Importance of Load Cells in Oil and Gas

/in Blog /by Jamie GlassInterface load cells are used in many facets of oil and gas, including to ensure safe lifting, enhance equipment integrity, provide accurate measurements in field operations, and even assist with optimal storage tank management. Our energy solutions include load cells that are used on rigs, downhole projects, extraction tools, and field support systems. We offer products ideal for harsh environments, extreme temperatures, and even submersible projects. Learn about our dry cell technology and IPCD product for downhole operations.

Load Cells Elevate Gantry Crane Performance

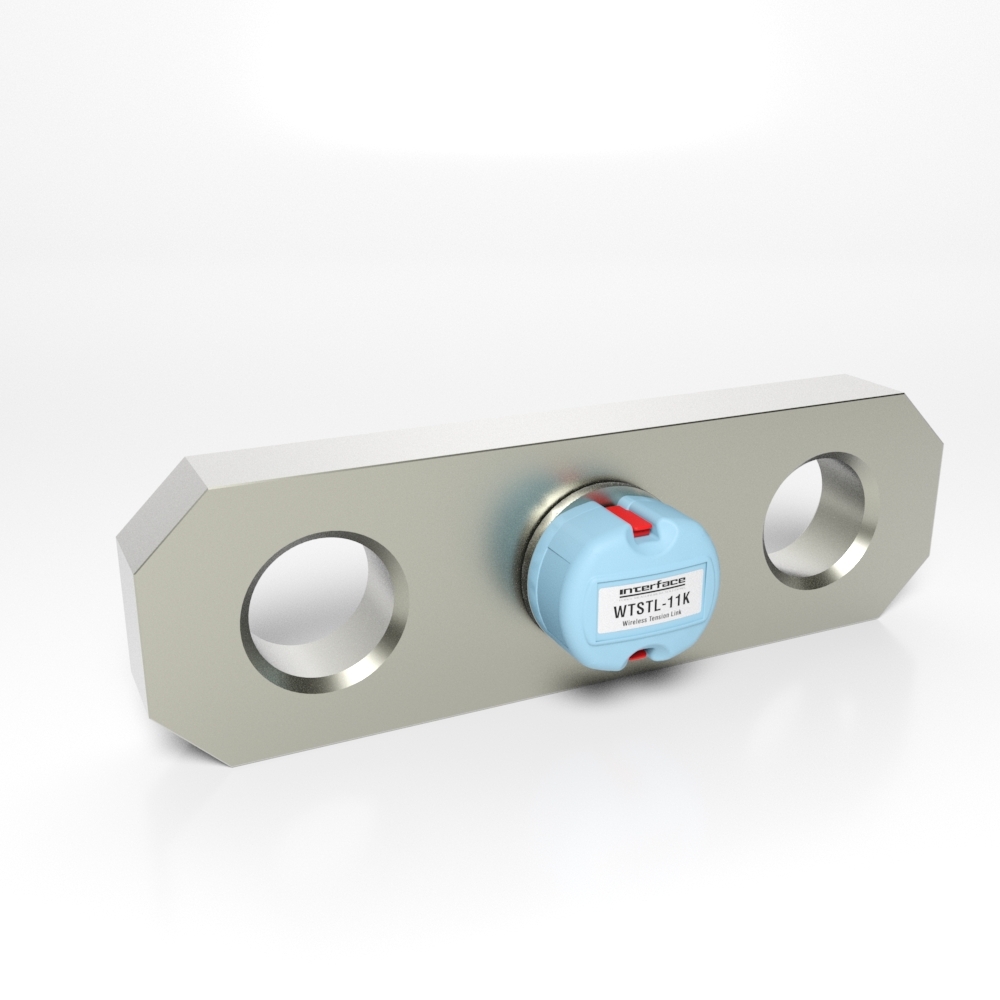

/in Blog /by Jamie GlassInterface load cells, load pins, tension links, wireless telemetry systems, and instrumentation devices are used for gantry crane safety monitoring, alert systems, overloading protection, retrofitting old equipment, and accurately measuring the tension, force, and weight during lifting operations.

Seaside Ports are Optimizing Efficiency and Safety Using Interface Sensor Technologies

/in Blog /by Jamie GlassInterface supplies measurement solutions to infrastructure and equipment makers for seaside ports, global trade shipping companies, and waterway terminals that heavily rely on quality measurement solutions. Our sensor technologies are used in cranes, gantry systems, lifting reach stackers, hoisting equipment, winches, anchors and mooring lines, plus weighbridges and scales. Ports turn to Interface for accurate load cells, load pins, shackles, tensions links, submersible solutions and wireless instrumentation.

A Great Force for Crane and Hoist Solutions

/in Blog /by Jamie GlassLCM-made products in Interface’s 35,000-plus catalog include Load Pins, Tension Links, and Shackles. This includes options for standard products, engineered-to-order, completely custom, ATEX, submersibles, and wireless solutions. Interface and recently acquired LCM Systems offer our customers powerful and diverse measurement devices for hoisting, winching, lifting, subsea, infrastructure, and industrial manufacturing applications.

Year in Review of Top Interface Solutions and Applications

/in Blog /by Jamie GlassInterface is at the forefront of innovative use cases and applications, providing quality devices worldwide to gather precision measurements. Interface unveils the top industry solutions, product use cases and applications that define force measurement in 2023.

Digging Into Interface Mining Industry Solutions

/in Blog /by Jamie GlassInterface products are essential for designing, testing, and utilizing mining equipment, machines, components, and systems. Our load cells, instrumentation, torque transducers, multi-axis sensors, load shackles, and tension links are used in tools and equipment for the mining industry. Interface measurement solutions help to optimize mine structural supports, digging equipment, and lifting processes to reduce wear and tear on equipment and prevent overloading, which can lead to costly downtime and maintenance.