Sensor technology is transforming safety and efficiency in cranes and heavy-lifting equipment. Interface load cells, load pins, shackles, and tension load links are integrated directly into the machinery to monitor forces during operation, provide real-time data on load status, and ensure safe operation.

The measurement data obtained from the measurement devices is crucial for preventing overloads, optimizing load distribution, and enhancing safety. By accurately measuring the weight and forces exerted during lifting, these sensors help operators stay within safe operational limits, preventing accidents and equipment failure.

These advanced measurement solutions are used across various applications, from construction and shipping to manufacturing and material handling. By providing precise, real-time data on load status, this technology empowers operators to make informed decisions, maximize productivity, and ensure the longevity of their equipment.

Interface Products for Crane Applications

Load cells play a crucial role in various crane types, from the towering giants of construction sites to the simple lifters in workshops. By accurately measuring the forces exerted during lifting operations, these sensors prevent overloads, optimize load distribution, enhance safety, and prevent machinery failure.

Here’s how this technology is applied across different crane types:

- Tower Cranes: Maintain stability and prevent overloads in high-rise construction.

- Mobile Cranes: Monitor weight and prevent tipping, especially on uneven terrain.

- Overhead Cranes: Ensure precise load handling and positioning in industrial settings.

- Marine Cranes: Account for vessel movement and maintain load stability during ship-to-shore operations.

- Gantry Cranes: Prevent overload and ensure stability when moving heavy items across their span.

- Smaller Cranes: Ensure safe lifting within capacity in workshops and service trucks.

Whether a massive gantry crane hoists shipping containers or a service truck crane lifts equipment, integrated load cells provide crucial real-time data, enabling operators to work safely and efficiently within the crane’s limits. This technology is essential for preventing accidents, optimizing performance, and extending the lifespan of heavy machinery.

Interface crane solutions are used in various industries and settings, including construction sites, warehouses, manufacturing facilities, transportation, healthcare facilities, maritime docks, aircraft testing and assembly, and infrastructure projects.

At Interface, safety and the well-being of others in environments using cranes are of the utmost importance due to the high risks associated with heavy loads, heights, and moving parts. The use of our load monitoring devices, such as load cells, tension links, load pins, or load shackles, is critical to ensuring efficient and safe crane operations.

Interface Engineered Solutions for Lifting Webinar Recap

/in Blog /by Jamie GlassInterface webinar Engineered Solutions for Lifting details force, torque, and weighing measurement products in lifting equipment like cranes, movers, rigging, simulators, drones, and medical devices. During this recorded webinar, experts provide tips for lifting, technical considerations, industry applications, load cells, instrumentation product reviews, and engineering recommendations for troubleshooting and preventing overloading. Sensors are central in lifting equipment to maintain safety, quality, compliance, and efficiency. Interface provides a useful product selection online resource for lifting applications. Watch to learn more.

Universal Load Cells 101

/in 101 Series, Blog /by Jamie GlassInterface Universal Load Cells offer the ability to measure both tension and compression forces. They are versitile force measurement solutions used for all types of applications that need to measure force, weight and shear. Interface’s Model 1200 and 1201 Series IO-Link Universal Load Cells are pancake style load cells that are IO-Link compatible with an open standard serial communication protocol that allows for the bi-directional exchange of data from sensors and devices.

Outlining Force Solutions for Structural Outrigging

/in Blog /by Jamie GlassInterface provides load cells and wireless technologies for structural outrigging. Force measurement sensor technologies provide high accuracy measurement of the outrigging equipment in test and actual use. The applications range from integrating sensors into outrigger equipment to using load cells for real-time monitoring of physical structures using outrigger supports. Interface load cells are used by outrigging engineers, civil engineers and heavy equipment manufacturers, oil and gas, construction industry and marine equipment companies.

Engineered Solutions for Lifting Webinar

/in Virtual Event /by Jamie GlassInterface’s technical webinar Engineered Solutions for Lifting details measurement devices used in lifting equipment, machines, and vehicles to improve operations and safety. Interface load cells and instrumentation are used to operate cranes, hoist heavy objects, and measure forces in infrastructure projects. Interface experts answer how load cells are used in safety monitoring for lifting equipment. Learn about Interface sensor products suited for integration into existing equipment and test and measurement projects.

Interface Measurement Solutions Support Smart Cities

/in Blog /by Jamie GlassInterface load cell technologies are used in the design and development of smart cities. Force measurement data is valuable for assessing and improving the overall efficiency and sustainability of a city. Load cells are versatile and essential tools for a diverse range of smart city applications. They provide accurate and reliable measurements that can be used to improve safety, resource management, and sustainability. Interface load cells can be used to measure a variety of parameters in smart city development and management, from water resources to recycling. They are used in all types of building material and structural tests.

Force Measurement Testing Improves Products and Consumer Safety

/in Blog /by Jamie GlassInterface sensor technologies are used every day for product testing to ensure quality performance and consumer safety. Our load cells are used to test various consumer products’ weight, torsion, tension, compression, fatigue, impact, and materials. Interface specialists in force, torque and weight testing solutions work with product designers, testing labs, and manufacturers to improve their products using our precision measurement devices.

How Load Cells Are Transforming the Construction Industry

/in Blog /by Jamie GlassInterface force measurement solutions are used for all types of construction applications from bridge and high-rise building projects, to foundation load tests and structural monitoring. Our load cells and instrumentation are used in crane and heavy lifting operations, material testing and equipment calibration.

Interface Solutions for Heavy Equipment

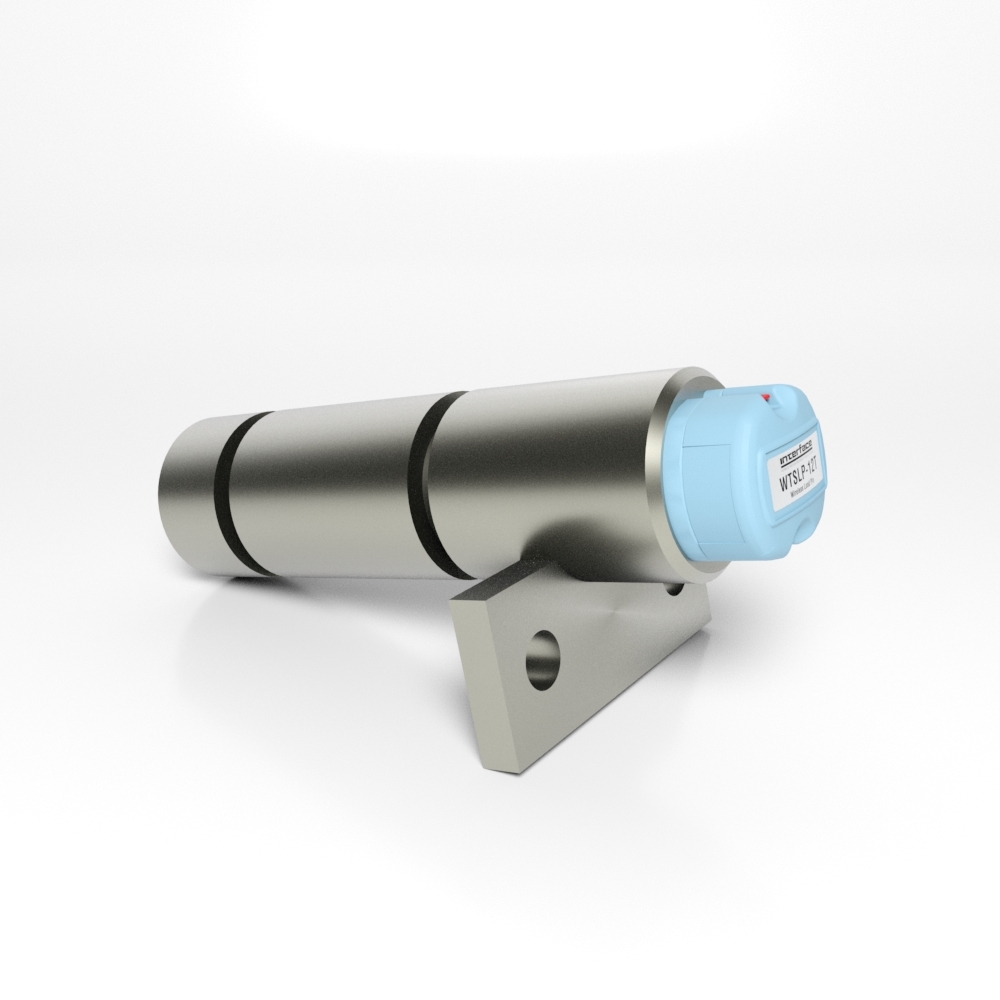

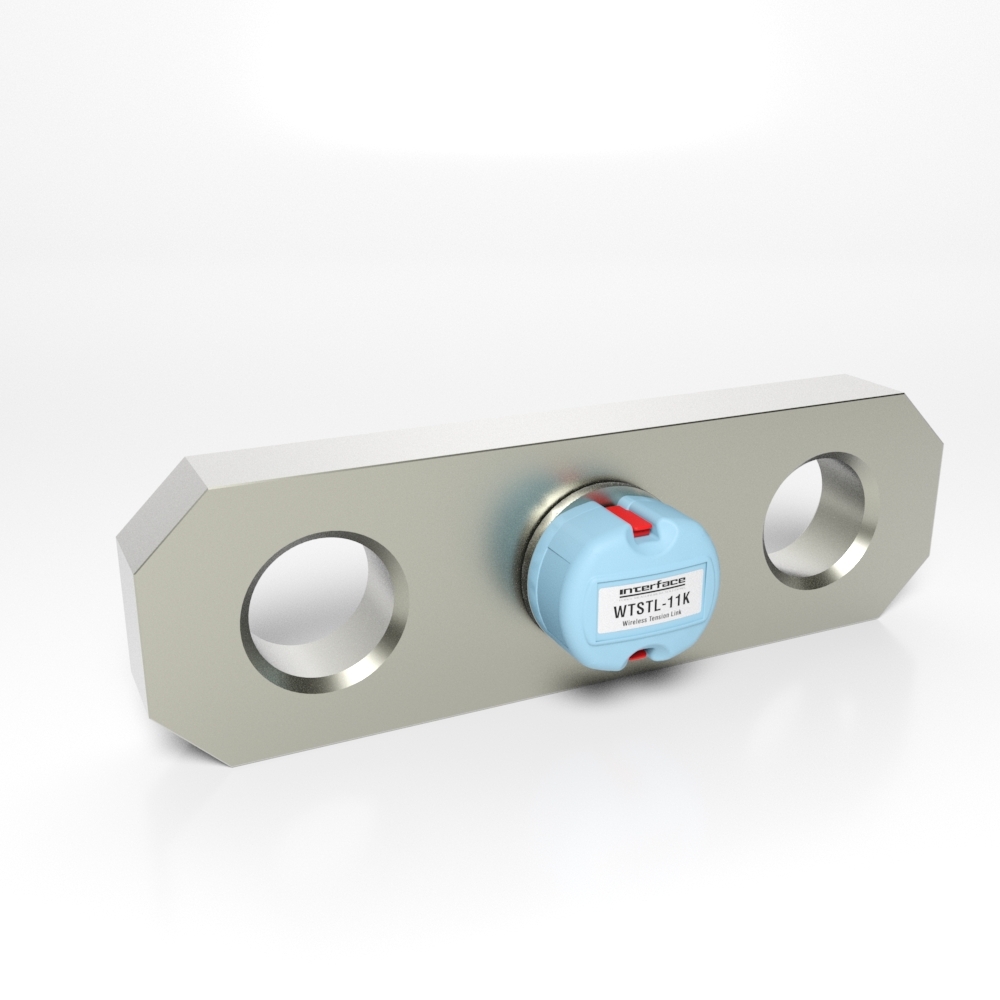

/in Blog, Infrastructure /by Jamie GlassInterface force measurement solutions play a crucial role in the design, testing, and use of heavy equipment and vehicles including excavators, bulldozers, loaders, cranes, lifts, mixers, pavers, and compactors. Many considerations in designing heavy machinery are mandated by force limitations and equipment performance testing. Measurement for testing and monitoring come from our high-accuracy load cells, load pins, tension links, load shackles and other weight, force and torque measurement products.

Rigging Engineers Choose Interface Measurement Solutions

/in Blog /by Jamie GlassInterface supports rigging engineers who design, plan, and oversee the rigging of heavy loads by providing high accuracy measurement solutions. The use of load cells to measure the weight of heavy loads, such as cranes, ships, rockets, theater equipment and machinery is on the rise. Rigging engineers use the data from load cells, load pins, load shackles, and tension links to ensure that the loads are not overloaded and that the rigging systems are properly designed for each use case. This often requires pairing the high accuracy sensor with instrumentation, and for versatility wireless telemetry systems are useful for rigging engineers.

Innovative Interface Lifting Solutions

/in Blog, Infrastructure, Maritime /by Jamie GlassInterface lifting solutions are utilized to accurately measure the weight or force being exerted on the lifting equipment. Our lload cells, load pins, tension links, wireless technologies are integrated into cranes, hoists, and lifting devices to provide precise load measurements. Interface lifting solutions apply to equipment and machines used at construction sites, warehouses, manufacturing facilities, transportation locations, healthcare facilities, and maritime docks. Lifting applications can vary, such as loading and unloading goods, positioning heavy equipment or machinery, transferring patients in healthcare settings, or lifting materials for construction purposes.