What is Static Error Band Output?

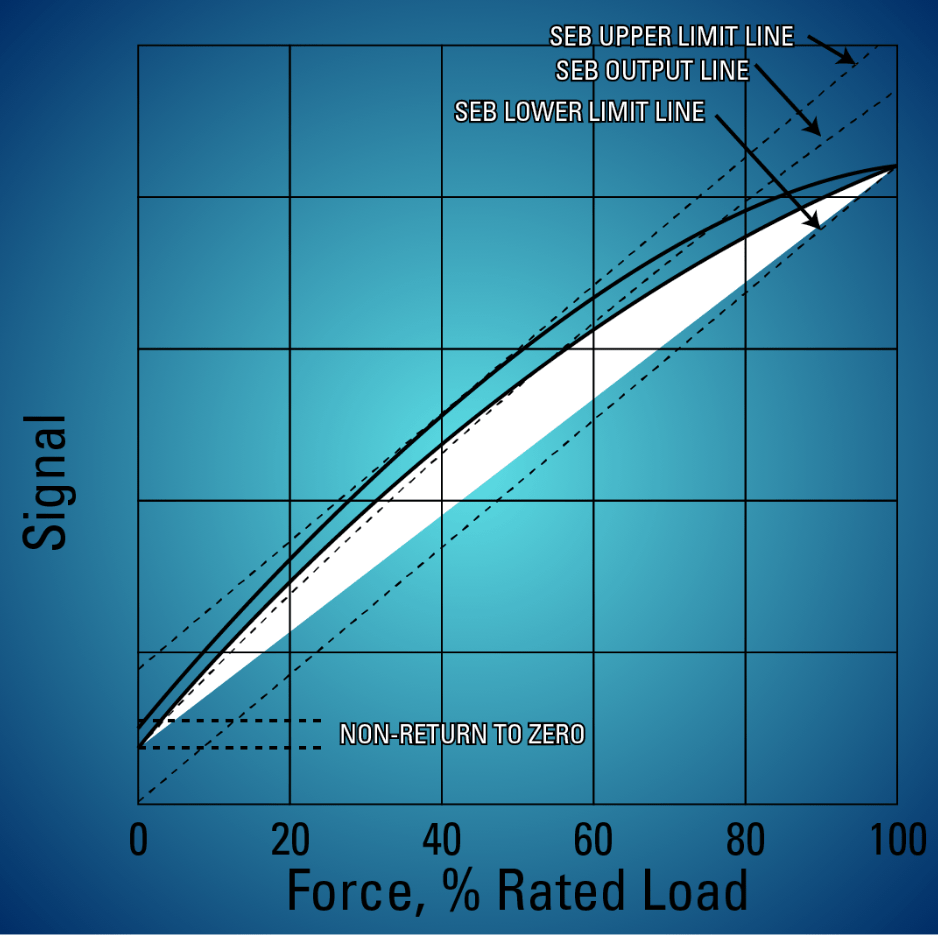

Static error band (SEB) measures the accuracy of a measuring device. Under static loading conditions, it is defined as the maximum deviation of the device’s output from a best-fit line through zero output. SEB includes the effects of non-linearity, hysteresis, and non-return to minimum load.

Static error band (SEB) measures the accuracy of a measuring device. Under static loading conditions, it is defined as the maximum deviation of the device’s output from a best-fit line through zero output. SEB includes the effects of non-linearity, hysteresis, and non-return to minimum load.

Static Error Band (SEB) Definition: A band encompassing all points on the ascending and descending curves centered on the best-fit straight line. It is expressed in units of %FS.

SEB is typically expressed as a percentage of full scale (FS), the maximum load the instrument can measure. For example, a load cell with a SEB of 0.1% FS would have a maximum error of 0.1% of its full-scale capacity.

SEB is an essential specification for measuring instruments used to make precise measurements, such as load cells, pressure transducers, and temperature sensors. A high SEB indicates that the device is inaccurate, and its measurements may be unreliable.

How to Calculate SEB

- Collect a series of calibration data points for the instrument under static loading conditions.

- Plot the calibration data on a graph, with the instrument’s output on the y-axis and the applied load on the x-axis.

- Fit a best-fit line through the calibration data points.

- Calculate the maximum deviation of the calibration data points from the best-fit line.

- Express the maximum deviation as a percentage of the full scale.

SEB is a helpful metric for comparing the accuracy of different measuring instruments. It is also important to note that SEB is only one measure of an instrument’s accuracy. Other factors, such as repeatability and reproducibility, should also be considered when selecting a device for a particular application.

What is SEB Output?

SEB output is the computed value for output at capacity derived from a line best fit to the actual ascending and descending calibration points and through zero output. It measures the accuracy of a measuring instrument under static loading conditions.

SEB output is the computed value for output at capacity derived from a line best fit to the actual ascending and descending calibration points and through zero output. It measures the accuracy of a measuring instrument under static loading conditions.

SEB Output Definition: The output at capacity is based on the best fit straight line.

The SEB output is the maximum deviation of the calibration points from this best-fit line. SEB output is typically expressed as a percentage of full scale (FS). SEB output is an essential specification for load cells and other measuring instruments used to make precise measurements.

Why Interface Uses SEB Output Instead of Terminal Output

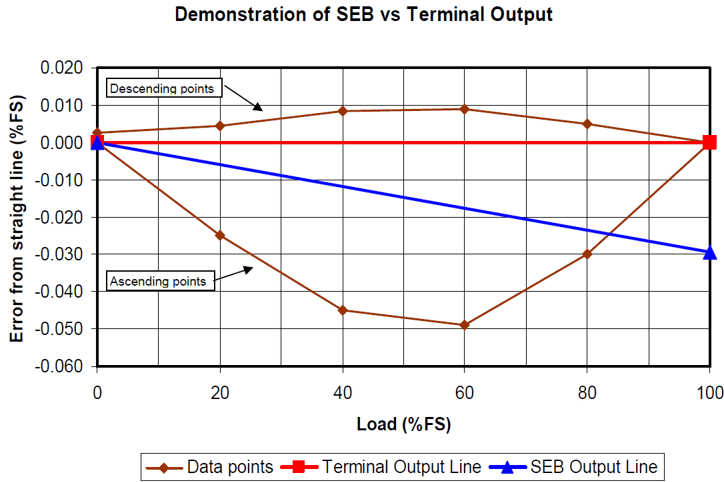

In the absence of alternate specific instructions, Interface uses the SEB output instead of the terminal output in straight-line scaling of a transducer to a digital indicator or analog signal conditioner. On average, the SEB output line yields the least error over the transducer range relative to the calibrated points.

SEB stands for Static Error Band and is a band on either side of a straight line through zero that is positioned to have equal maximum error above and below the line. The line extends from zero to the SEB output. The line considers both ascending and descending calibration points.

The plot below allows error visualization relative to the SEB and terminal output lines for a typical load cell calibration curve with ascending and descending points.

In this example, the SEB equals 0.03%FS, and the SEB line is no more than 0.03%FS away from any calibration point. The terminal line, in contrast, has a maximum deviation from calibration points of 0.05%FS. The plot shows that the ascending calibrated curve and the SEB line cross near 80%FS, often a more common measurement area in an application than 100%FS.

Source: Levar Clegg

Benefits of Using SEB Output

- SEB output is a more accurate measure of the load cell’s accuracy than terminal output.

- SEB output is less sensitive to environmental factors and noise than terminal output.

- SEB output is easier to understand.

- SEB output confirms that the measurements are accurate and the results are reliable.

How does a test engineer use SEB Output when selecting a load cell and instrumentation system?

Test engineers use SEB Output when selecting a load cell and instrumentation system to ensure the system is accurate enough for the intended application. The selection of a load cell is often based on an SEB Output that is less than the required accuracy of their application. For example, if an engineer needs to achieve measurements with an accuracy of 0.1%, they will select a load cell with a SEB Output of less than 0.1% FS.

It is crucial to consider the instrumentation system’s accuracy to measure the load cell’s output. The instrumentation system should have an accuracy equal to or greater than the accuracy of the load cell.

For additional information about specification values, be sure to watch this short clip from our Demystifying Specifications Webinar Recap

Test and measurement professionals can select an accurate, reliable, valuable load cell and instrumentation system following these tips.